6061 aluminium alloy

6061 Aluminium alloy composition by mass:[4] The mechanical properties of 6061 greatly depend on the temper, or heat treatment, of the material.

The typical value for thermal conductivity for 6061-T6 at 25 °C (77 °F) is around 152 W/m K. The fatigue limit under cyclic load is 97 MPa (14 ksi) for 500,000,000 completely reversed cycles using a standard RR Moore test machine and specimen.

[12] Note that aluminium does not exhibit a well defined "knee" on its S-N curve, so there is some debate as to how many cycles equates to "infinite life".

Also note the actual value of fatigue limit for an application can be dramatically affected by the conventional de-rating factors of loading, gradient, and surface finish.

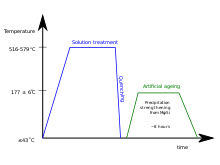

Different aluminium heat treatments control the size and dispersion of Mg2Si precipitates in the material.

Iron, manganese, and chromium secondary phases (Fe2Si2Al9, (Fe, Mn, Cr)3SiAl12) often form as inclusions in the material.

[13] Grain sizes in aluminium alloys are heavily dependent upon the processing techniques and heat treatment.

For deep draw and complex shapes, and for the avoidance of spring-back, an aluminium hot stamping process (Hot Form Quench) can be used, which forms a blank at a elevated temperature (~ 550 C) in a cooled die, leaving a part in W-temper condition before artificial aging to the T6 full strength state.

Aluminium 6061 can be forged into flat or round bars, rings, blocks, discs and blanks, hollows, and spindles.

Centrifugally cast 6061 is ideal for larger rings and sleeve applications that exceed the limitations of most wrought offerings.