AT4

[10] The name also doubles as an alpha-phonetic word play on the weapon's role, due to "AT" being a common military abbreviation for "anti-tank".

[5] FFV began research on a replacement for the m/68 in 1976, deliberately designing an individual anti-armour weapon that would not be able to defeat the heavy armour protection of MBTs (main battle tanks) in frontal engagements, believing that to be counterproductive.

[13] Even before the AT4 had been adopted by Sweden, it was entered into a United States Army competition for a new anti-tank weapon mandated by Congress in 1982 when the FGR-17 Viper failed as a replacement for the M72 LAW.

The US Army reported to Congress in November 1983 that the FFV AT4 came the closest to meeting all the major requirements established to replace the M72 LAW,[14] with the Armbrust coming in second.

[15] Though very impressed with the simplicity and durability of the tested version of the AT4, the US Army saw some room for improvement, specifically the addition of rear and front bumpers on the launch tube and changes to the sights and slings.

[16] The Swedish Army also recognized these improvements and subsequently adopted the Americanized version of the AT4 as the Pansarskott m/86 (Pskott m/86), with the addition of a forward folding hand grip to help steady the AT4 when being aimed and fired.

Due to the urban combat conditions that US military forces faced regularly during the Iraq War, the US Army Close Combat Systems manager in charge of purchases of the AT4 suspended orders for the standard version of the AT4; US military forces instead only ordered the AT4 CS (Confined Space) version.

In a single-use disposable gun, the barrel only needs to be able to contain a single pressure spike when firing, when it can be disposed of, even if it is ruined, burnt-out and strained, unlike traditional guns which are required to survive many pressure spikes without failure and thus need to be strongly overbuilt and made of heat-proof materials.

This lightweight and thin barrel and low pressure, combined with the almost complete lack of recoil, means that relatively large projectiles (comparable to those found in mortars and artillery systems) can be utilised, which would otherwise be impossible in a man-portable weapon.

In the system originally developed by FFV for the Carl Gustaf, a plastic blowout plug is placed at the centre rear of the shell casing containing the projectile and propellant, which itself is enclosed in the AT4 outer tube.

This version uses a saltwater countermass in the rear of the launcher to absorb the back blast; the resulting spray captures and dramatically slows down the pressure wave, allowing troops to fire from enclosed areas.

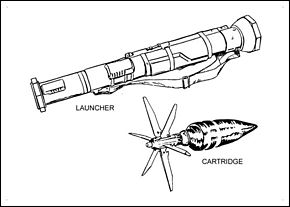

Unlike the heavier Carl Gustaf, the AT4 outer tube is built to take the stress of just one firing; it is not reusable and cannot be reloaded.

However, as the cost of each launcher makes regular live-fire training very expensive, practice versions exist that are identical in operation but fire reloadable 9×19mm or 20mm tracer ammunition.

The heavier nose cap allows either to penetrate light walls or windows before exploding, or to be "skipped" off the ground for an air burst.

[26] M136A1 AT4CS-RS – American variant with a unique bi-metal warhead design, specially developed to maximize behind-armor effects for higher kill probability.

The weapon is capable of firing from confined spaces (CS) and features a reduced sensitivity (RS) explosive, with an armor penetration of over 350 mm.

Its effective range is 20–300 m.[27][28][9] XM919 Individual Assault Weapon (also known as AT4CS TW) – American future variant, to enter service in 2025, and be delivered by 2029 for USD $500 million.