Aeroponics

Some growers prefer aeroponic systems over other hydroponic methods the increased aeration of the nutrient solution provides greater oxygenation to the plant roots, stimulating growth and aiding in the prevention of pathogen formation.

Researchers have highlighted aeroponics as a valuable, simple, and rapid method for preliminary screening of genotypes for resistance to specific seedling blights or root rots.

The degradation of the spray caused by mineralization of mist heads hampers the delivery of the water nutrient solution, resulting in an environmental imbalance within the air culture system.

To address this issue, special low-mass polymer materials have been developed and are utilized to prevent mineralization in the next generation of hydro-atomizing misting and spray jets.

These findings highlight the potential of aeroponics not only as a valuable research tool for studying nutrient uptake but also as a means to monitor plant health and optimize crop cultivation in closed environments.

K. Hubick evaluated aeroponics as a means to consistently produce plants with minimal water stress, which can be utilized in drought or flood physiology experiments.

Advanced commercial systems go a step further by incorporating data gathering, monitoring, analytical feedback, and internet connectivity to various subsystems, enhancing overall efficiency and productivity.

For instance, Leptadenia reticulata, an important medicinal plant with low reproductive rates through both seeds and cuttings,[15] has found easier propagation through aeroponics (Mehandru et al., 2014).

[17] It boasts a higher success rate compared to overhead misters, which have drawbacks such as the need for large volumes of water, potential unsanitary conditions, uneven misting coverage, and possible leaching of foliar nutrients (Peterson et al., 2018).

[17] In essence, cloning has become easier with the use of aeroponic apparatus, as it initiates faster and cleaner root development through a sterile, nutrient-rich, highly oxygenated, and moist environment (Hughes, 1983).

The efforts of GTi in developing an all-plastic aeroponic method and apparatus controlled by a microprocessor have ushered in a new era of artificial life support for plants, allowing them to grow naturally without the use of soil or traditional hydroponics.

[18] In 1982, Isaac Nir in Israel developed a patent for an aeroponic apparatus that utilized compressed low-pressure air to deliver a nutrient solution to suspended plants held by styrofoam[clarification needed] inside large metal containers.

[19] In 1976, British researcher John Prewer conducted a series of aeroponic experiments in the UK, where lettuces were grown from seed to maturity in 22 days using polyethylene film tubes.

[20] In collaboration with John Prewer, a commercial grower named Kings Nurseries on the Isle of Wight used a different design of aeroponics system in 1984 to grow strawberry plants.

The strawberries flourished, yielding a bountiful crop that was highly appreciated by customers, especially the elderly, who valued the cleanliness, quality, and flavor of the fruit, as well as the convenience of picking it without stooping.

In 1983, Richard Stoner filed a patent for the first microprocessor interface designed to deliver tap water and nutrients into an enclosed aeroponic chamber made of plastic.

[6] Stoner's company, Genesis Technology Inc, played a pioneering role in manufacturing, marketing, and applying large-scale closed-loop aeroponic systems in greenhouses for commercial crop production.

His accomplishment garnered attention, and he was invited for an interview on NPR, where he highlighted the significance of aeroponics in terms of water conservation, both in modern agriculture and even in space exploration.

[11][23] Following these early endeavors, plant experiments were conducted on various missions involving Bangladesh, China, and joint Soviet-American efforts, including Biosatellite II, Skylab 3 and 4, Apollo-Soyuz, Sputnik, Vostok, and Zond.

At the organismic level, several species including pine, oat, mung bean, lettuce, cress, and Arabidopsis thaliana exhibited decreased seedling, root, and shoot growth under low gravity conditions.

The goal was to develop a natural liquid biocontrol solution for closed-loop hydroponic systems that could prevent plant diseases and increase yields without the need for pesticides.

Results from NASA's enclosed environment bean experiments on the MIR space station and shuttle confirmed that ODC promoted increased germination rates, better sprouting, enhanced growth, and activated natural plant disease mechanisms.

The sensors monitor various environmental factors, including lighting intensity, spectrum, and photoperiod, temperature, CO2 levels, relative humidity, irrigation, as well as plant-derived ethylene and volatile organic compound (VOC) scrubbing.

Aeroponic systems use hydro-atomized sprays to deliver nutrients, resulting in minimal water usage, enhanced root oxygenation, and excellent plant growth.

By removing the substrate requirement, planting and harvesting processes are simplified, automation becomes easier, the weight and volume of expendable materials are reduced, and a potential pathway for pathogen transmission is eliminated.

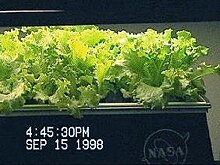

[2][failed verification] In 1999, NASA allocated funding to support the development of an inflatable low-mass aeroponic system (AIS) for high-performance food production in both space and on Earth.

The use of relatively small solution volumes in aeroponics, combined with the limited exposure of roots to the hydro-atomized mist, minimizes root-to-root contact and reduces the spread of pathogens among plants.

[34][35] AeroFarms, leveraging Harwood's patented aeroponic technology, currently operates the largest indoor vertical farm in the world based on its annual growing capacity in Newark, New Jersey.

In a notable development in 2005, Dr. Neil Reese of South Dakota State University conducted GMO research using aeroponics to grow genetically modified corn.

This development holds significant historical importance as it marks the first time a nation has specifically prioritized aeroponics to bolster its agricultural sector, promote economic growth in farming, meet rising demands, improve food quality, and increase overall production.