Autogenerative high-pressure digestion

First described by R. Lindeboom of University of Wageningen (WUR) in 2011,[1] a batch reactor was pressurized to 58 bar, yielding a methane concentration of 96% in the resulting biogas.

The result is biogas with a higher methane content, which requires less upgrading to meet natural gas standards, ultimately reducing processing costs.

For example, the methane-producing archaea species Methanocaldococcus, Methanothermococcus, Methanopyrus and Methanotorris have been found in hydrothermal vents in the ocean floor.

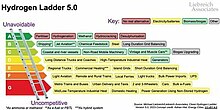

On Michael Liebreich's hydrogen ladder 5.0, this form of biogas upgrading is at step C. [10] This is considerably higher than applications as fuel in vehicles.

These are spread over steps D to G.[11] Although the technique is usually used as a fermentation process for thick liquid flows and solid biomass, it can also be applied as anaerobic Wastewater treatment.