Pantograph (transport)

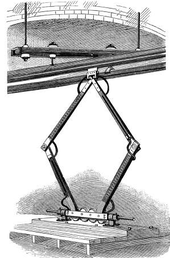

A pantograph (or "pan" or "panto") is an apparatus mounted on the roof of an electric train, tram or trolley buses[1] to collect power through contact with an overhead line.

Early versions include the bow collector, invented in 1889 by Walter Reichel, chief engineer at Siemens & Halske in Germany,[2][3] and a flat slide-pantograph first used in 1895 by the Baltimore and Ohio Railroad.

The most common type of pantograph today is the so-called half-pantograph (sometimes Z-shaped), which evolved to provide a more compact and responsive single-arm design at high speeds as trains got faster.

[11] While a pantograph is mainly used to power a railway traction unit, there are certain cases where it has a function other than traction: The electric transmission system for modern electric rail systems consists of an upper, weight-carrying wire (known as a catenary) from which is suspended a contact wire.

Trolley poles are still used by trolleybuses, whose freedom of movement and need for a two-wire circuit makes pantographs impractical, and some streetcar networks, such as the Toronto streetcar system, which have frequent turns sharp enough to require additional freedom of movement in their current collection to ensure unbroken contact.

Pantographs with overhead wires are now the dominant form of current collection for modern electric trains in city street, main and high speed lines because, although more fragile than a third rail system, they are safer for public (protection by distance), they may also allow higher voltages (especially AC ones) and higher speed.

Pantographs are typically operated by compressed air from the vehicle's braking system, either to raise the unit and hold it against the conductor or, when springs are used to effect the extension, to lower it.

For high-voltage systems, the same air supply is used to "blow out" the electric arc when roof-mounted circuit breakers are used.

Most rapid transit systems are powered by a third rail, but some use pantographs, particularly ones that involve extensive above-ground running.

Most hybrid metro-tram or 'pre-metro' lines whose routes include tracks on city streets or in other publicly accessible areas, such as (formerly) line 51 of the Amsterdam Metro, the MBTA Green Line, RTA Rapid Transit in Cleveland, Frankfurt am Main U-Bahn, and San Francisco's Muni Metro, use overhead wire, as a standard third rail would obstruct street traffic and present too great a risk of electrocution.

These may consist of physical ground-level infrastructure, or use energy stored in battery packs to travel over short distances without overhead wiring.

The entire metro systems of Sydney, Madrid, Barcelona, Porto, Shanghai, Hong Kong, Seoul, Kobe, Fukuoka, Sendai, Jaipur, Chennai, Mumbai and Delhi use overhead wiring and pantographs (as well as certain lines of the metro systems in Beijing, Chongqing, Noida, Hyderabad, Jakarta, Tokyo, Osaka, Nagoya, Singapore, Sapporo, Budapest, and Mexico City).

Numerous railway lines use both third rail and overhead power collection along different portions of their routes, generally for historical reasons.

As such, the line required railcars that featured pantographs as well as third rail shoes, and since the overhead was a very small portion of the system, only a few cars would be so equipped.

Due to the many level crossings, it was deemed difficult to install a third rail on the rest of the older line's single track.

Newer electric traction units may use more sophisticated methods which detect the disturbances caused by arcing at the point of contact when the graphite strips are damaged.

[22] In Europe, the automatic dropping device is mandatory for trains with operational speeds of 160 km/h or 120 km/h and higher if one or several pantographs are used respectively.