Automotive industry in the United States

Employment In the United States, the automotive industry began in the 1890s and, as a result of the size of the domestic market and the use of mass production, rapidly evolved into the largest in the world.

Their U.S. market share has dropped steadily as numerous foreign-owned car companies have built factories in the U.S. As of 2012, Toyota had 31,000 U.S. employees, compared to Ford's 80,000 and Chrysler's 71,100.

Selden filed a series of amendments to his application which stretched out the legal process, resulting in a delay of 16 years before the patent was granted on 5 November 1895.

State governments began to use the corvee system to maintain roads, an implementation of required physical labor on a public project on the local citizens.

Part of their motivation was the needs of farmers in rural areas attempting to transport their goods across rough, barely functioning roads.

The materials involved altered during World War I to accommodate the heavier trucks on the road and were responsible for widespread shift to macadam highways and roadways.

While the Model A was successful, Ford lost ground to GM and eventually Chrysler, as auto buyers looked to more upscale cars and newer styling.

GM followed Ford by expanding overseas, including purchasing England's Vauxhall Motors in 1925, Germany's Opel in 1929, and Australia's Holden in 1931.

The acquisition of Dodge gave Chrysler the manufacturing facilities and dealer network that it needed to significantly expand production and sales.

General Motors wanted automobiles to be not just utilitarian devices, which Ford emphasized, but status symbols that were highly visible indicators of an individual's wealth.

All factories were enlarged and converted, many new ones such as Ford's Willow Run and Chrysler's Detroit Arsenal Tank Plant were built, and hundreds of thousands more workers were hired.

[25] Experts anticipated that Detroit would learn advanced engineering methods from the aviation industry that would result in great improvements for postwar civilian automobiles.

The company introduced numerous product and marketing innovations, but its small size made it difficult to compete with the Big Three and struggled financially.

The 1950s were also noted for perhaps one of the biggest miscues in auto marketing with the Ford Edsel, which was the result of unpopular styling and being introduced during an economic recession.

The introduction of the Interstate Highway System[26] and the suburbanization of America made automobiles more necessary[27] and helped change the landscape and culture in the United States.

[32] In response to this the domestic auto makers developed compact-sized cars, such as the Ford Falcon, Chevrolet Corvair, Studebaker Lark, and Plymouth Valiant.

Competitors were quickly introduced, including the Chevrolet Chevelle SS, Dodge R/T (Coronet and Charger), Plymouth Road Runner/GTX, Ford Torino, and AMC's compact SC/Rambler.

Safety and environmental issues during the 1960s led to stricter government regulation of the auto industry, spurred in part by Ralph Nader and his book: Unsafe at Any Speed: The Designed-in Dangers of the American Automobile.

Under the National Traffic and Motor Vehicle Safety Act of 1966, Federal Motor Vehicle Safety Standards required shoulder belts for front passengers, front head restraints, energy-absorbing steering columns, ignition-key warning systems, anti-theft steering column/transmission locks, side marker lights and padded interiors starting in 1968.

[38] In response to this, the domestic auto makers introduced new compact and sub-compact cars, such as the Ford Pinto and Maverick, the Chevrolet Vega, and the AMC Gremlin, Hornet and Pacer.

GM had a string of miscues starting with the Chevrolet Vega, which developed a reputation for rapidly rusting and having major problems with the aluminium engine.

Several large acquisitions (Electronic Data Systems and Hughes Aircraft Company) diverted management attention away from their main industry.

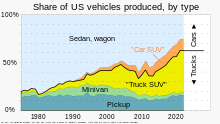

Due to the Corporate Average Fuel Economy standards differentiating between passenger cars and light trucks, the automakers were able to sell large and heavy vehicles without fear of the CAFE fines.

Chrysler, purchased in 2007 by a private equity firm, had weak financial backing, was the most heavily dependent on light truck sales, and had few new products in their pipeline.

[54] The CEOs of the Big Three requested government aid in November 2008, but sentiment in Congress was against the automakers, especially after it was revealed that they had flown to Washington, D.C., on their private corporate jets.

Several months later, President Obama formed the Presidential Task Force on the Auto Industry to decide how to handle GM and Chrysler.

[56] Ford did not request any government assistance, but as part of their downsizing decided in 2009 to sell Volvo Cars, which was acquired by Chinese Geely in the summer of 2010, and phased out their Mercury division in 2011.

(Ford had previously sold Aston Martin in 2007, and Land Rover and Jaguar Cars in early-June 2008 and its controlling-interest in Mazda in November 2008).

In terms of specific types of vehicles, the new decade has meant Chrysler having an emphasis on its Ram trucks and the Jeep Cherokee SUV, both of which had "hefty sales" for 2014 according to a news report.

On January 28, 2021, General Motors announced that it will become 100% all-electric by 2035 in order to become compliant with the Biden Administration's tougher automotive emission standards and electric vehicle goals due to worsening climate change and air pollution.