Balanced-arm lamp

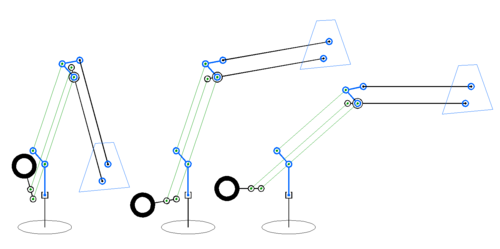

Many lamp brands (such as the Anglepoise, originator of the concept, and Luxo L-1), as well as other devices, use this principle.

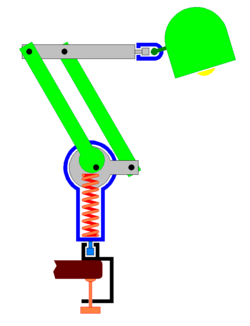

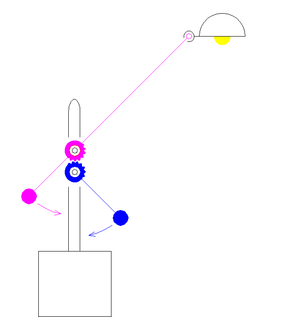

Springs can be located on the mechanical equivalent of the forearm or the upper arm, or both, as well as nearer to the base.

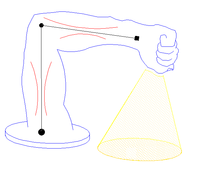

This lamp has a stiff flexible tube as its forearm, and a spring-balanced arm to support it near the middle.

The lamp cap rotates the same direction as the upper arm and forearm.

With this technique the tension spring has a double function: it controls both the forearm and the upper arm.

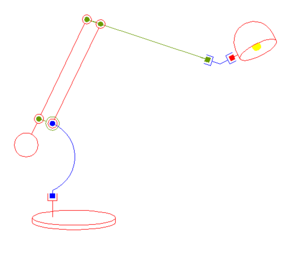

A stronger spring set controls the upper arm, which has three parallel bars (see photo, left).

(There is a less stable construction with two parallel bars in the upper arm which is less expensive to manufacture.)

As with most balanced-arm lamps, the whole assembly can rotate in the horizontal plane, and is mounted on a stable foot.

The Roller chain cable connects this arm parallel to the forearm (yellow).

In this construction (commonly found in Italian lamps) gravity causes the parallelogram to deform such that the gap between the long arms becomes smaller.

This in turn increases pressure on the rubber in the gap, and the resulting friction holds the arm in place.

Disadvantages are that the lamp is inherently less balanced, thus it needs a heavy stand to remain stable.

The balance that is required is shown by the following formula: This lamp has a heavy base, with a parallelogram pantograph construction formed by bars which are all hinged on each other.

One long bar extends past the parallelogram construction and has a counterweight.

One short bar also extends past the parallelogram construction and holds the lamp cap.

This lamp stand has a complex construction with matching narrow openings.