Biodiesel

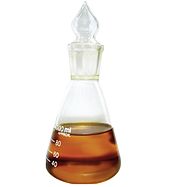

Biodiesel is a renewable biofuel, a form of diesel fuel, derived from biological sources like vegetable oils, animal fats, or recycled greases, and consisting of long-chain fatty acid esters.

Biodiesel production has evolved significantly, with early methods including the direct use of vegetable oils, to more advanced processes like transesterification, which reduces viscosity and improves combustion properties.

Despite these challenges, biodiesel remains a key component in the global strategy to reduce reliance on fossil fuels and mitigate the impacts of climate change.

Rudolf Diesel's prime model, a single 10 ft (3.05 m) iron cylinder with a flywheel at its base, ran on its own power for the first time in Augsburg, Germany, on 10 August 1893 running on nothing but peanut oil.

The French Government at the time thought of testing the applicability to power production of the Arachide, or earth-nut, which grows in considerable quantities in their African colonies, and can easily be cultivated there."

Belgium, France, Italy, the United Kingdom, Portugal, Germany, Brazil, Argentina, Japan and China were reported to have tested and used vegetable oils as diesel fuels during this time.

On 31 August 1937, Georges Chavanne of the University of Brussels (Belgium) was granted a patent for a "Procedure for the transformation of vegetable oils for their uses as fuels" (fr.

Backup diesel-fueled generators allow companies to avoid damaging blackouts of critical operations at the expense of high pollution and emission rates.

[57] The use of these generators in residential areas around schools, hospitals, and the general public result in substantial reductions in poisonous carbon monoxide and particulate matter.

It was noted that the higher viscosity and the greater cetane rating of biodiesel over traditional petrodiesel lead to poor atomization, as well as mixture penetration with air during the ignition delay period.

Using alcohols of higher molecular weights improves the cold flow properties of the resulting ester, at the cost of a less efficient transesterification reaction.

Although it would not be efficient to raise animals (or catch fish) simply for their fat, use of the by-product adds value to the livestock industry (hogs, cattle, poultry).

Feedstock yield efficiency per unit area affects the feasibility of ramping up production to the huge industrial levels required to power a significant percentage of vehicles.

To foster the biofuel industry, governments have implemented legislations and laws as incentives to reduce oil dependency and to increase the use of renewable energies.

The mandate to manufacture biofuel with a 20% palm oil component - known as B20 - for the transport sector was first rolled out in January 2020 but faced delays due to movement curbs imposed to contain coronavirus outbreaks.

[124][125] Some propose that fuel only be made from non-edible vegetable oils such as camelina, jatropha or seashore mallow[126] which can thrive on marginal agricultural land where many trees and crops will not grow, or would produce only low yields.

However, environmental organizations, for example, Rainforest Rescue[131] and Greenpeace,[132] criticize the cultivation of plants used for biodiesel production, e.g., oil palms, soybeans and sugar cane.

The deforestation of rainforests exacerbates climate change and sensitive ecosystems are destroyed to clear land for oil palm, soybean and sugar cane plantations.

The Environmental Protection Agency published data in January 2012, showing that biofuels made from palm oil will not count towards the renewable fuels mandate of the United States as they are not climate-friendly.

These include: If land use change is not considered and assuming today's production methods, biodiesel from rapeseed and sunflower oil produce 45%-65% lower greenhouse gas emissions than petrodiesel.

Another study using controlled experimental conditions also showed that fatty acid methyl esters, the primary molecules in biodiesel, degraded much faster than petroleum diesel in sea water.

It is generally recognized that using biodiesel in place of diesel results in a substantial reduction in regulated gas emissions, but there has been a lack of information in research literature about the non-regulated compounds which also play a role in air pollution.

[152][failed verification] This could be because of enhanced corrosion over time due to oxidation of the unsaturated molecules or increased water content in biodiesel from moisture absorption.

However, B20 biodiesel blend has been found to provide maximum increase in thermal efficiency, lowest brake-specific energy consumption, and lower harmful emissions.

The feedstock used to make the biodiesel alters the fuel’s properties by changing the average carbon chain length and number of double bonds present in the fatty acid methyl esters.

In addition to its projected high yield, algaculture — unlike crop-based biofuels — does not entail a decrease in food production, since it requires neither farmland nor fresh water.

Several groups in various sectors are conducting research on Jatropha curcas, a poisonous shrub-like tree that produces seeds considered by many to be a viable source of biodiesel feedstock oil.

[174] SG Biofuels also claims that additional benefits have arisen from such strains, including improved flowering synchronicity, higher resistance to pests and disease, and increased cold weather tolerance.

[178] A group at the Russian Academy of Sciences in Moscow published a paper in 2008, stating that they had isolated large amounts of lipids from single-celled fungi and turned it into biodiesel in an economically efficient manner.

This organism was recently discovered in the rainforests of northern Patagonia and has the unique capability of converting cellulose into medium length hydrocarbons typically found in diesel fuel.