Biorefinery

Palm empty fruit bunches (EFB) are an abundant lignocellulosic residues from the palm oil/biodiesel industry, the conversion of this residue into ethanol, heat and power, and cattle feed were evaluated according to techno-economic principles,[15] the scenarios under study shown reduced economic benefits, although their implementation represented a reduction in the environmental impact (climate change and fossil fuel depletion) compared to the traditional biodiesel production.

The integration of microalgae and Jatropha as a viable route for the production of biofuels and biochemicals has been analyzed in the United Arab Emirates (UAE) context.

In regard to the pulp and paper industry; lignin is a natural polymer co-generated and is generally used as boiler fuel to generate heat or steam to cover the energy demand in the process.

The valorization of municipal solid waste through integrated mechanical biological chemical treatment (MBCT) systems for the production of levulinic acid has been studied,[27] the revenue from resource recovery and product generation (without the inclusion of gate fees) is more than enough to out- weigh the waste collection fees, annual capital and operating costs.

One of the main goals of biorefineries is to contribute to a more sustainable industry by the conservation of resources and by reducing greenhouse gas emissions and other pollutants.

[28] Life cycle assessment (LCA) is a methodology to evaluate the environmental load of a process, from the extraction of raw materials to the end use.

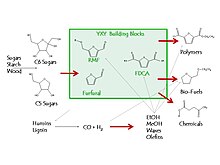

[34] The majority of the LCA studies for the valorization of food waste have been focused on the environmental impacts on biogas or energy production, with only few on the synthesis of high value-added chemicals;[35] hydroxymethylfurfural (HMF) has been listed as one of the top 10 bio-based chemicals by the US Department of Energy; the LCA of eight food waste valorization routes for the production of HMF shows that the most environmentally favorable option uses less polluting catalyst (AlCl3) and co-solvent (acetone), and provides the highest yield of HMF (27.9 Cmol%), metal depletion and toxicity impacts (marine ecotoxicity, freshwater toxicity, and human toxicity) were the categories with the highest values.

[37] This industry has consolidated as the highest consumer of biomass; and uses not only wood as feedstock, it is capable of processing agricultural waste as bagasse, rice straw and corn stover.

[40] The fully operational Blue Marble Energy company has multiple biorefineries located in Odessa, WA and Missoula, MT.

The biorefinery utilizes Source Separated Organics from the metro Edmonton region, open pen feedlot manure, and food processing waste.

[41] Novamont has converted old petrochemical factories into biorefineries, producing protein, plastics, animal feed, lubricants, herbicides and elastomers from cardoon.

[55] In South Africa, Numbitrax LLC bought a Blume Biorefinery system for producing bioethanol as well as additional high-return offtake products from local and readily available resources such as the prickly pear cactus.