British Aerospace 146

[6] The chosen configuration had a high wing and a T-tail to give good short-field performance, while the aircraft was to be powered by four 6,500 lbf thrust Avco Lycoming ALF 502H turbofan engines.

Such a configuration was considered by British Aerospace to be advantageous in the event of a single engine failure, offering "exceptional three-engine performance" that would appeal to operators in mountainous environments and from "high, hot or poor grade airfields".

[6] The programme was initially launched with backing from the UK government, which agreed to contribute 50% of the development costs in return for a share of the revenues from each aircraft sold.

Prior to the first flight, British Aerospace had forecast that the smaller 146-100 would significantly outsell the 146-200 variant; however, airlines showed a higher level of interest in the larger 146-200.

[18][19] Due to the sales performance of the BAe 146, British Aerospace announced a development project in early 1991 to produce a new variant of the type, powered by two turbofan engines instead of four, that was offered to airlines as a regional jet aircraft.

Dubbed the new regional aircraft (NRA), other proposed alterations from the BAe 146 included the adoption of a new enlarged wing and a lengthened fuselage.

The Avro RJ series also featured a modernised cockpit with EFIS replacing the analogue ADI, HSI, and engine instrumentation.

[21] An arrangement between British Aerospace and Khazanah Nasional would have opened an Avro RJ production line in Malaysia, but this deal collapsed in 1997.

In 1992, the regional aircraft operation blew a hole in the then British Aerospace's balance sheet, forcing it to take a £1bn write-off.

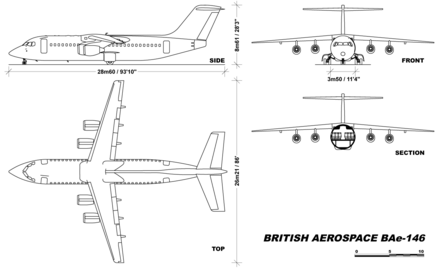

Instead, the BAe 146 features a large airbrake with two petals below the tail rudder at the rear of the fuselage, which has the advantage of being usable during flight and allowing for steep descent rates if required.

[29] Grigg highlighted factors such as design simplicity, using off-the-shelf components where possible, and the internal use of firm cost targets and continuous monitoring.

British Aerospace also adopted a system of cost guarantees between component suppliers and the operators of the BAe 146 to enforce stringent requirements.

[30] Drawing on experience from the Hawker Siddeley Trident and the Airbus A300, both the fuselage and wing were carefully designed for a reduced part-count and complexity.

[32] The undercarriage of the aircraft is toughened to resist damage and stability is maximised by the placement of landing gear, of particular value when operating from rough airstrips.

[14] The engines are not fitted with thrust reversers, instead the aircraft has a clamshell air brake in the tail and full width spoilers on the wings.

[33] The BAe 146 is a quadjet powered by four Avco Lycoming ALF 502 turbofan engines, which are fixed on pylons underneath the aircraft's high wing.

Advantages of adopting the four-engine configuration include greater redundancy and superior takeoff performance from short runways, as well as in hot and high conditions.

The BAe 146 was announced in January 1987 to have been selected to launch the first jet services from London City Airport; it was chosen due to its unmatched flying characteristics and ability to operate from so-called STOLports.

National Jet Express also continues to operate a fleet of BAe 146-300QT freighters on behalf of Qantas Freight, providing overnight services to and from curfew-restricted Sydney Airport under a type-specific exemption.

[55][56] However, due to airlines favouring a lower initial price rather than minimising seat-mile costs, the definitive 146-300 emerged as a less extreme development.

An RJ115 variant, the same physical size, but with an increased MTOW and different emergency exits, was marketed, but never entered production;[58][59] it seated 116 as standard or up to a maximum of 128 in a high-density layout.

[63] Upgrades and alterations made to the type include new glass cockpit avionics, additional fuel tanks, increased steep approach, and unpaved runway operation capabilities, and being outfitted with defensive aids; however, a rear cargo door was not introduced.

BAE has stated that the 146M is suitable for performing airlift, medical evacuation, para-drop, surveillance, and inflight refueling operations.

The RJX series used Honeywell AS977 turbofans for greater efficiency (15% less fuel burn, 17% increased range), quieter performance, and 20% lower maintenance costs.

BAE reached an agreement with Druk Air and British European in early 2002 in which the airlines agreed not to enforce their firm orders for the RJX.

BAE explored the possibility of manufacturing 14 "hybrid" aircraft, but British European at least was unwilling to accept the risk of operating a unique type.

[67] Firefighting air tanker versions of both the BAe 146 and the Avro RJ85 have been manufactured by the conversion of aircraft previously operated by airlines in scheduled passenger service.

[68] Several organizations carry out such conversions, including U.S.-based Minden Air Corporation, Neptune Aviation Services, and Aero-Flite, a U.S. subsidiary of Canadian-based Conair Group.

[69][70][71][72] In January 2012, Conair Group announced its arrangements to market and promote the Avro RJ85 as a major air tanker platform.

[77] Airbus and Rolls-Royce abandoned the E-Fan X programme several months before the planned first flight as the commercial aircraft industry changed its priorities during the COVID-19 pandemic.