Cam (mechanism)

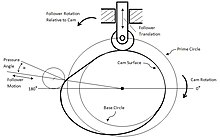

The cam can be a simple tooth, as is used to deliver pulses of power to a steam hammer, for example, or an eccentric disc or other shape that produces a smooth reciprocating (back and forth) motion in the follower, which is a lever making contact with the cam.

Here, the cam profile is commonly symmetric and at rotational speeds generally met with, very high acceleration forces develop.

Thus, in practice, the points at which lift begins and ends mean that a tangent to the base circle appears on the profile.

Applications include machine tool drives, such as reciprocating saws, and shift control barrels in sequential transmissions, such as on most modern motorcycles.

The purpose and detail of implementation influence whether this application is called a cam or a screw thread, but in some cases, the nomenclature may be ambiguous.

Non-invertible functions, which require the groove to self-intersect, can be implemented using special follower designs.

[13] A face cam that implements three outputs for a single rotational input is the stereo phonograph, where a relatively constant lead groove guides the stylus and tonearm unit, acting as either a rocker-type (tonearm) or linear (linear tracking turntable) follower, and the stylus alone acting as the follower for two orthogonal outputs to representing the audio signals.

[14] This type of cam was used for example in mechanical timekeeping clocking-in clocks to drive the day advance mechanism at precisely midnight and consisted of a follower being raised over 24 hours by the cam in a spiral path which terminated at a sharp cut off at which the follower would drop down and activate the day advance.

Where timing accuracy is required as in clocking-in clocks these were typically ingeniously arranged to have a roller cam follower to raise the drop weight for most of its journey to near its full height, and only for the last portion of its travel for the weight to be taken over and supported by a solid follower with a sharp edge.

Cam mechanisms appeared in China at around 600 BC in the form of a crossbow trigger-mechanism with a cam-shaped swing arm.

[20] Likewise, more recent research indicates that cams were used in water-driven trip hammers by the latter half of the Western Han Dynasty (206 BC – 8 AD) as recorded in the Huan Zi Xin Lun.

[21] During the Tang dynasty, the wooden clock within the water-driven astronoical device, the spurs inside a water-driven armillary sphere, the automated alarm within a five-wheeled sand-driven clock, artificial paper figurines within a revolving lantern, all utilized cam mechanisms.

[22] The Chinese hodometer which utilized a bell and gong mechanism is also a cam, as described in the Song Shi.

[23] Out of these examples, the water-driven pestle and the water driven wind box both have two cam mechanisms inside.

[24] Cams that rotated continuously and functioned as integral machine elements were built into Hellenistic water-driven automata from the 3rd century BC.

[27] Waldo J Kelleigh of Electrical Apparatus Company patented the adjustable cam[28] in the United States in 1956 for its use in mechanical engineering and weaponry.