Carburetor

[7] Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG).

In most cases (except for the accelerator pump), the driver pressing the throttle pedal does not directly increase the fuel entering the engine.

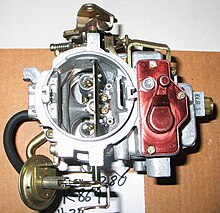

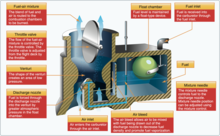

The main metering circuit usually consists of barrel/s which reduces to a narrow part where the air is at its highest speed before widening again, forming a venturi.

Fuel is introduced into the air stream through small tubes leading from the main jet being driven by the difference in pressure to that at the float bowl.

Downstream of the venturi is a throttle (usually in the form of a butterfly valve) which is used to control the amount of air entering the carburetor.

[11] At the same time, the reduced manifold vacuum results in less fuel flow through the idle and/or off-idle circuits.

Additional fuel is required (for a given amount of air) to start and run the engine until it warms up, provided by a choke valve.

While the engine is warming up the choke valve is partially closed, restricting the flow of air at the entrance to the carburetor.

Prior to the late 1950s the choke was manually operated by the driver, often using a lever or knob on the dashboard.

To remove the excess fuel, many carburetors with automatic chokes allow it to be held open (by manually, depressing the accelerator pedal to the floor and briefly holding it there while cranking the starter) to allow extra air into the engine until the excess fuel is cleared out.

The idle jet is set at some constant value by the carburetor manufacturer, thus flowing a specified amount of fuel.

Many carburetors use an off-idle circuit, which includes an additional fuel jet which is briefly used as the throttle starts to open.

This jet is located in a low-pressure area caused by the high air speed near the (partly closed) throttle.

As the airflow through the carburetor increases the reduced manifold vacuum pulls the power valve open, allowing more fuel into the main metering circuit.

[12] When the driver presses the throttle pedal, a small piston or diaphragm pump injects extra fuel directly into the carburetor throat.

[13] The accelerator pump can also be used to "prime" an engine with extra fuel prior to attempting a cold start.

Problems of fuel boiling and vapor lock can occur in carbureted engines, especially in hotter climates.

As the flowrate of the air in the chamber increases, the diaphragm moves outward (upward) which opens the needle valve to admit more fuel, allowing the engine to generate more power.

A balanced state is reached which creates a steady fuel reservoir level, that remains constant in any orientation.

[22][23] All three of these engines used surface carburetors, which operated by moving air across the top of a vessel containing the fuel.

[33] One of the last motorsport users of carburetors was NASCAR, which switched to electronic fuel injection after the 2011 Sprint Cup series.

EEC legislation required all vehicles sold and produced in member countries to have a catalytic converter after December 1992.

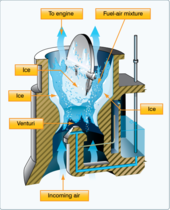

The conditions during the descent to landing are particularly conducive to icing, since the engine is run at idle for a prolonged period with the throttle closed.

[35] If the engine is operating at idle RPM, another method to prevent icing is to periodically open the throttle, which increases the air temperature within the carburetor.