Carvel (boat building)

This is in contrast to "plank first" or "shell first" methods, where the outer skin of the hull is made and then reinforced by the insertion of timbers that are fitted to that shape.

That change has been suggested to save building, fitting out and maintenance costs (though previously it was thought to be to achieve better sailing performance – something which, against the presumptions of many maritime historians, can be shown not to have happened).

Carvel construction allows hull shape to be determined by design, whilst planking-first relies on the "eye" of the builder.

[7]: 61 Northern Europe used clinker construction for the period discussed above, and into the 15th century (and continued to do so for many small craft into the present day).

The different methods were known of by mariners in both places, but when, for instance, Mediterranean galleys were employed by the French and English during the Hundred Years' War, shipwrights familiar with carvel work had to be recruited to carry out maintenance and repairs.

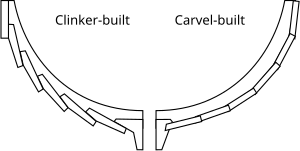

Clinker (lapstrake) construction involves longitudinal overlapping "riven timber" (split wood) planks that are fixed together over very light scantlings.

A carvel boat has a smoother surface which gives the impression that it is more hydrodynamically efficient since the exposed edges of the clinker planking appear to disturb the streamline and cause drag.

A structural benefit of clinker construction is that it produces a vessel that can safely twist and flex around its long axis (running from bow to stern).

The same problem in providing for concentrated loads creates difficulties siting and supporting a centerboard or deep keel, which is much needed when sailing across or close to the wind.

Traditional carvel methods leave a small gap between each plank that is caulked with any suitable soft, flexible, fibrous material, sometimes combined with a thick binding substance, which would gradually wear out and the hull would leak.

When the boat was beached for a length of time, the planks would dry and shrink, so when first refloated, the hull would leak badly unless re-caulked, a time-consuming and physically demanding job.

Many small boats, especially light plywood skiffs, are built without any mechanical fasteners such as nails and lag screws at all, as the glue is far stronger.