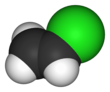

Vinyl chloride

Vinyl chloride monomer is among the top twenty largest petrochemicals (petroleum-derived chemicals) in world production.

[2] The United States remains the largest vinyl chloride manufacturing region because of its low-production-cost position in chlorine and ethylene raw materials.

Vinyl chloride that is released by industries or formed by the breakdown of other chlorinated chemicals can enter the air and drinking water supplies.

[8][9] Globally, approximately 40 million tonnes of PVC resin are produced per year,[10] requiring a corresponding amount of vinyl chloride monomer.

When vinyl chloride producers shifted to using the thermal cracking of EDC described below, some used byproduct HCl in conjunction with a colocated acetylene-based unit.

[15] In the United States and Europe, mercury-catalyzed routes widely used in the 20th century have been superseded by more economical and greener processes based on ethylene.

Two steps are involved, chlorination and dehydrochlorination: Numerous attempts have been made to convert ethane directly to vinyl chloride.

Even though residence time and temperature are carefully controlled, it produces significant quantities of chlorinated hydrocarbon side products.

As the nitrogen purge gas exits the interstitial space it passes through an analyzer that detects whether any vinyl chloride is leaking from the internal sphere.

Inhibited vinyl chloride may be stored at normal atmospheric conditions in suitable pressure vessels.

Uninhibited vinyl chloride may be stored either under refrigeration or at normal atmospheric temperature in the absence of air or sunlight but only for a duration of a few days.

Because of its low boiling point, liquid vinyl chloride will undergo flash evaporation (i.e., autorefrigerate) upon its release to atmospheric pressure.

Fire may release toxic hydrogen chloride (HCl) and carbon monoxide (CO) and trace levels of phosgene.

[23][24] Vinyl chloride can polymerise rapidly due to heating and under the influence of air, light and contact with a catalyst, strong oxidisers and metals such as copper and aluminium, with fire or explosion hazard.

[6][25] Since it is a gas under most ambient conditions, primary exposure is via inhalation, as opposed to the consumption of contaminated food or water, with occupational hazards being highest.

Dermal exposure effects are thickening of skin, edema, decreased elasticity, local frostbites, blistering, and irritation.

[35] In 1968, Mutchler and Kramer, two Dow researchers, reported their finding that exposures as low as 300 ppm caused liver damage in vinyl chloride workers thus confirming earlier animal data in humans.

"[37] Vinyl chloride was first reported to induce angiosarcoma of the liver in 1974[38] and further research has demonstrated the carcinogenicity of VC to other organs and at lower concentrations,[39][40] with evidence now extending to jobs associated with poly(vinyl chloride) exposure, indicating the need for prudent control of PVC dust in the industrial setting.

[41] Vinyl chloride is now an IARC group 1 carcinogen known to cause hepatic angiosarcoma (HAS) in highly exposed industrial workers.

[45] In 1997 the U.S. Centers for Disease Control and Prevention (CDC) concluded that the development and acceptance by the PVC industry of a closed loop polymerization process in the late 1970s "almost completely eliminated worker exposures" and that "new cases of hepatic angiosarcoma in vinyl chloride polymerization workers have been virtually eliminated.

"[48] EPA's 2001 updated Toxicological Profile and Summary Health Assessment for vinyl chloride in its Integrated Risk Information System (IRIS) database lowers EPA's previous risk factor estimate by a factor of 20 and concludes that "because of the consistent evidence for liver cancer in all the studies [...] and the weaker association for other sites, it is concluded that the liver is the most sensitive site, and protection against liver cancer will protect against possible cancer induction in other tissues.

The bacteria species Nitrosomonas europaea can degrade a variety of halogenated compounds including trichloroethylene, and vinyl chloride.