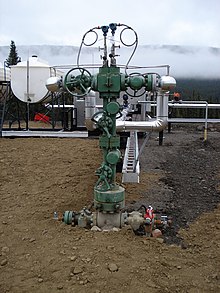

Christmas tree (oil well)

Examples of subsea include conventional, dual bore, mono bore, TFL (through flow line), horizontal, mudline, mudline horizontal, side valve, and TBT (through-bore tree) trees.

When the well and facilities are ready to produce and receive oil or gas, tree valves are opened and the formation fluids are allowed to go through a flow line.

A tree often provides numerous additional functions including chemical injection points, well intervention means, pressure relief means, monitoring points (such as pressure, temperature, corrosion, erosion, sand detection, flow rate, flow composition, valve and choke valve position feedback), and connection points for devices such as down hole pressure and temperature transducers (DHPT).

On producing wells, chemicals or alcohols or oil distillates may be injected to preclude production problems (such as blockages).

They are frequently manufactured from blocks of steel containing multiple valves rather than being assembled from individual flanged components.

This is especially true in subsea applications where the resemblance to Christmas trees no longer exists given the frame and support systems into which the main valve block is integrated.

This feature means that if control fluid fails the well will automatically shut itself in without operator action.

The intention is to allow rigging down equipment from the top of the tree with the well flowing while preserving the two-barrier rule.

However, avoiding delaying production for a day is usually too small a gain to be worth the extra expense of having a Christmas tree with a second swab valve.

Subsea trees are available in either vertical or horizontal configurations with further speciality available such as dual bore, monobore, concentric, drill-through, mudline, guidelineless or guideline.