Coffee production

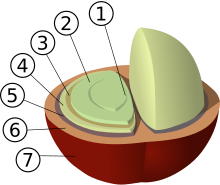

The cherries ripen around eight months after the emergence of the flower, by changing color from green to red, and it is at this time that they should be harvested.

The plant eventually grows small white blossoms that drop and are replaced by green berries.

This discernment typically only occurs with growers who harvest for higher end/specialty coffee where the pickers are paid better for their labor.

Red berries, with their higher aromatic oil and lower organic acid content, are more fragrant, smooth, and mellow.

This is done either by the classic ferment-and-wash method or a newer procedure variously called machine-assisted wet processing, aquapulping or mechanical demucilaging.

In the ferment-and-wash method of wet processing, the remainder of the pulp is removed by breaking down the cellulose by fermenting the beans with microbes and then washing them with large amounts of water.

The fermentation process has to be carefully monitored to ensure that the coffee does not acquire undesirable, sour flavors.

[6] The fermentation process produces wastewater that contains a high organic load, which should be prevented from entering fresh water supplies.

[8][9] However, by eliminating the fermentation step and prematurely separating fruit and bean, mechanical demucilaging can remove an important tool that mill operators have of influencing coffee flavor.

Furthermore, the ecological criticism of the ferment-and-wash method increasingly has become moot, since a combination of low-water equipment plus settling tanks allows mill operators to carry out fermentation with limited pollution.

[5][dubious – discuss] The downside in using a machine assisted process or "semi-wash" is a high chance of the beans being chipped or damaged.

[11] Ecologically sensitive farms reprocess the wastewater along with the shell and mucilage as compost to be used in soil fertilization programs.

The coffee cherries are spread out in the sun, either on large concrete or brick patios or on matting raised to waist height on trestles.

The drying operation is the most important stage of the process, since it affects the final quality of the green coffee.

Coffee that has not been dried sufficiently will be too moist and prone to rapid deterioration caused by the attack of fungi and bacteria.

The dried cherries are stored in bulk in special silos until they are sent to the mill where hulling, sorting, grading and bagging take place.

Literally translated from Indonesian, Giling Basah means "wet grinding", and refers to an earlier "hulling" step than compared to the common washed/wet process.

In this process, farmers remove the outer skin from the cherries mechanically, using locally built pulping machines.

Following this waiting period, the mucilage is washed off and the parchment coffee is partially dried in the sun and sold at 25% to 40% moisture content.

Fermentation can start immediately as honey dried coffee beans have a remaining "sugar" layer which is vulnerable to any sort of mold and offers feeding ground for bacteria.

The processor needs to rake the green coffee beans 2–3 times per hour to ensure a safe drying process.

Honey coffees often have a syrupy body with enhanced sweetness, round acidity and earthy undertones.

[3] This is done to improve the appearance of green coffee beans and eliminate a byproduct of roasting called chaff.

Coffees also may be graded by the number of imperfections (broken, under-ripe, or otherwise defective beans; pebbles; sticks; etc.)

Importing the beans to Europe required a lengthy sea voyage around the Horn of Africa, which ultimately changed the coffee's flavor due to age and exposure to saline air.

Once the Suez Canal was opened, shipment time to Europe was greatly reduced and coffee with flavor less affected by salt and age began arriving.

[17] Although it is still widely debated and subject to personal taste, certain types of green coffee are believed to improve with age – especially strains valued for their low acidity, such as beans from Indonesia or India.

[citation needed] Decaffeination is the process of extracting caffeine from green coffee beans prior to roasting.

Coffee that is poorly stored may develop a burlap-like taste known as "bagginess", and its positive qualities may fade.

In recent years, the specialty coffee market has begun to utilize enhanced storage methods.