Common rail

For every 90° of rotation, four plunger pumps allowed a constant injection pressure of 3,000 pounds per square inch (210 bar; 21 MPa), with fuel delivery to individual cylinders being shut off by valves in the injector lines.

Camshaft-operated mechanical timing valves were used to supply the spring-loaded Brice/CAV/Lucas injectors, which injected through the side of the cylinder into the chamber formed between the pistons.

Dr. Shohei Itoh and Masahiko Miyaki of the Denso Corporation developed the ECD-U2 common rail system, mounted on the Hino Ranger truck.

Unfortunately Fiat were in a poor financial state at this time, so the design was acquired by Robert Bosch GmbH for refinement and mass production.

[6] The first passenger car to use this system was the 1997 Alfa Romeo 156 with a 2.4-L JTD engine,[7] and later that same year, Mercedes-Benz introduced it in their W202 model.

The main suppliers of modern common rail systems are Bosch, Delphi Technologies, Denso, and Siemens VDO (now owned by Continental AG).

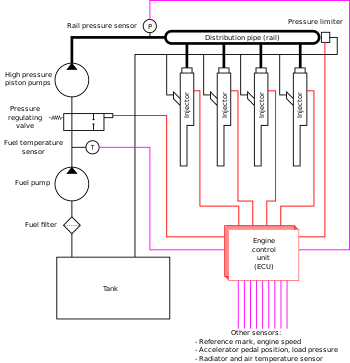

[8] The automotive manufacturers refer to their common rail engines by their own brand names: Solenoid or piezoelectric valves make possible fine electronic control over the fuel-injection time and quantity, and the higher pressure that the common rail technology makes available provides better fuel atomisation.

This simplifies the purpose of the high-pressure pump in that it only needs to maintain a target pressure (either mechanically or electronically controlled).

Third-generation[vague] common rail diesels now feature piezoelectric injectors for increased precision, with fuel pressures up to 2,500 bar (250 MPa; 36,000 psi).