Computer-aided manufacturing

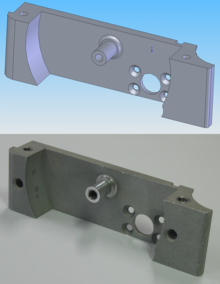

Traditionally, CAM has been numerical control (NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components are generated in CAD.

[12] Historically, CAM software was seen to have several shortcomings that necessitated an overly high level of involvement by skilled CNC machinists.

In some cases, such as improperly set up CAM software or specific tools, the CNC machine required manual editing before the program will run properly.

None of these issues were so insurmountable that a thoughtful engineer or skilled machine operator could not overcome for prototyping or small production runs; G-Code is a simple language.

At least in the United States, there is a shortage of young, skilled machinists entering the workforce able to perform at the extremes of manufacturing; high precision and mass production.

This is occurring primarily in three arenas: Most machining progresses through many stages,[16] each of which is implemented by a variety of basic and sophisticated strategies, depending on the part design, material, and software available.