Corrosion fatigue

Nearly all engineering structures experience some form of alternating stress, and are exposed to harmful environments during their service life.

Materials with high specific strength are being developed to meet the requirements of advancing technology.

The effects of corrosive environments on the fatigue behavior of metals were studied as early as 1930.

To meet the needs of advancing technology, higher-strength materials are developed through heat treatment or alloying.

Fracture mechanics uses pre-cracked specimens, effectively measuring crack-propagation behavior.

For this reason, emphasis is given to crack-propagation velocity measurements (using fracture mechanics) to study corrosion fatigue.

Specimen fracture occurs when the stress-intensity-factor range is equal to the applicable threshold-stress-intensity factor for stress-corrosion cracking.

Common types of corrosion include filiform, pitting, exfoliation, intergranular; each will affect crack growth in a particular material in a distinct way.

[7] In materials where the maximum applied-stress-intensity factor exceeds the stress-corrosion cracking-threshold value, stress corrosion adds to crack-growth velocity.

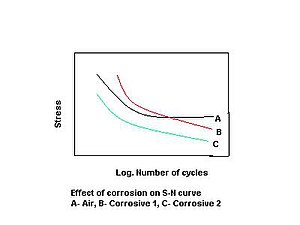

In the most-general case, corrosion-fatigue crack growth may exhibit both of the above effects; crack-growth behavior is represented in the schematic on the left..