Cotton gin

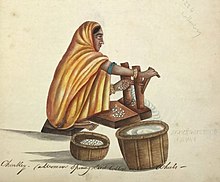

[4] The Indian worm-gear roller gin was invented sometime around the 16th century[5] and has, according to Lakwete, remained virtually unchanged up to the present time.

It revolutionized the cotton industry in the United States, but also inadvertently led to the growth of slavery in the American South.

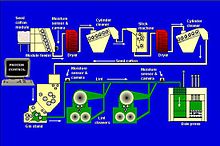

[7] Modern automated cotton gins use multiple powered cleaning cylinders and saws, and offer far higher productivity than their hand-powered precursors.

Many simple seed-removing devices had been invented, but until the innovation of the cotton gin, most required significant operator attention and worked only on a small scale.

The seeds are too big to fit through the holes, and are thus removed from the rotating cotton by the metal plate, before they fall into a collecting pot.

The lint cleaners again use saws and grid bars, this time to separate immature seeds and any remaining foreign matter from the fibers.

[4] Another innovation, the incorporation of the crank handle in the cotton gin, first appeared sometime during the late Delhi Sultanate or the early Mughal Empire.

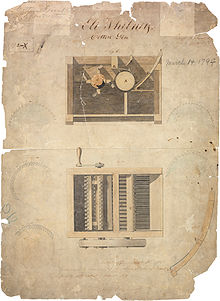

[19] There is slight controversy over whether the idea of the modern cotton gin and its constituent elements are correctly attributed to Eli Whitney.

The popular image of Whitney inventing the cotton gin is attributed to an article on the subject written in the early 1870s and later reprinted in 1910 in The Library of Southern Literature.

In this article, the author claimed Catharine Littlefield Greene suggested to Whitney the use of a brush-like component instrumental in separating out the seeds and cotton.

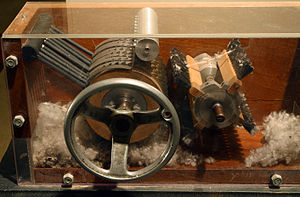

[20] Whitney's cotton gin model was capable of cleaning 50 pounds (23 kg) of lint per day.

The model consisted of a wooden cylinder covered by rows of slender wires which caught the fibers of the cotton bolls.

[21] The comb-like teeth of the grids were closely spaced, preventing the seeds, fragments of the hard dried calyx of the original cotton flower, or sticks and other debris attached to the fibers from passing through.

[24] McCarthy's gin was adopted for cleaning the Sea Island variety of extra-long staple cotton grown in Florida, Georgia and South Carolina.

It cleaned cotton several times faster than the older gins, and, when powered by one horse, produced 150 to 200 pounds of lint a day.

[26] For a decade and a half after the end of the Civil War in 1865, a number of innovative features became widely used for ginning in the United States.

Robert and his wife, Mary Collett, later moved to Mexia, Texas, built a system gin, and obtained related patents.

However, the selling point for most gin owners was the accompanying cost savings while producing cotton both more speedily and of higher quality.

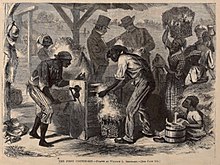

[34] With Eli Whitney's gin, cotton became a tremendously profitable business, creating many fortunes in the Antebellum South.

Additionally, the greatly expanded supply of cotton created strong demand for textile machinery and improved machine designs that replaced wooden parts with metal.

[37] The invention of the cotton gin led to increased demands for slave labor in the American South, reversing the economic decline that had occurred in the region during the late 18th century.

Because of that inadvertent effect on American slavery, which ensured that the South's economy developed in the direction of plantation-based agriculture (while encouraging the growth of the textile industry elsewhere, such as in the North), the invention of the cotton gin is frequently cited as one of the indirect causes of the American Civil War.

The lint cleaners again use saws and grid bars, this time to separate immature seeds and any remaining foreign matter from the fibers.