Critical path method

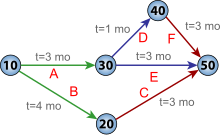

[1] A critical path is determined by identifying the longest stretch of dependent activities and measuring the time[2] required to complete them from start to finish.

CPM was used for the first time in 1966 for the major skyscraper development of constructing the former World Trade Center Twin Towers in New York City.

This process determines which activities are "critical" (i.e., on the longest path) and which have no float/slack or "total float" zero (i.e., can be delayed without making the project longer).

This might insert dead time (total float) into the schedule on the activities on that path prior to the sunrise due to needing to wait for this event.

Critical path drag analysis has also been used to optimize schedules in processes outside of strict project-oriented contexts, such as to increase manufacturing throughput by using the technique and metrics to identify and alleviate delaying factors and thus reduce assembly lead time.

[11] It can be achieved by shifting more resources towards the completion of that activity, resulting in decreased time spent and often a reduced quality of work, as the premium is set on speed.

[14] A related concept is called the critical chain, which attempts to protect activity and project durations from unforeseen delays due to resource constraints.

A schedule generated using the critical path techniques often is not realized precisely, as estimations are used to calculate times: if one mistake is made, the results of the analysis may change.

However, the structure of critical path analysis is such that the variance from the original schedule caused by any change can be measured, and its impact either ameliorated or adjusted for.

The method currently used by most project management software is based on a manual calculation approach developed by Fondahl of Stanford University.