Cummins B Series engine

Since its introduction, three generations of the B series engine have been produced, offered in both inline-four and inline-six configurations in multiple displacements.

[1] Unlike earlier diesel engines the B-series Cummins used direct injection and did not need glow plugs for cold starting.

[2] The engine was first manufactured in Rocky Mount, North Carolina, and other plants were later added in Mexico, Brazil, Turkey, and Darlington, UK.

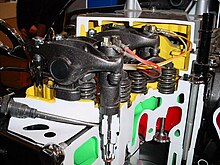

One unusual feature of the ISB is that it is a multi-valve pushrod engine design, with four valves per cylinder (popularly referred to as the "24-Valve" Cummins).

It is an all-iron engine with forged steel connecting rods, an assembled camshaft, and a cast aluminum intake manifold.

[4] Midway through model year 1998, the Dodge Ram switched from the 6BT to the ISB to meet updated emissions requirements.

The standard output, which was the same as the previous engines was rated to 235 hp (175 kW; 238 PS) and 460 lb⋅ft (624 N⋅m) when equipped with either a manual transmission or automatic.

The high output ISB was rated at 245 hp (183 kW; 248 PS) and 505 lb⋅ft (685 N⋅m), with only a NV5600 six-speed manual transmission available.

The high output engine was different in a few ways from the standard output engine; it had higher compression (17.3:1), powdered metal valve seat inserts, a larger flywheel, the Bosch fuel system was reworked to allow higher fuel flows, and fuel-injection timing was altered.

For the 2003 model year, the Cummins was introduced with Bosch high pressure common rail fuel injection, again increasing power output.

Engine torque is slightly reduced with the Mercedes G56 6-speed manual transmission at 350 hp (261 kW; 355 PS) and 610 lb⋅ft (827 N⋅m).

The 2007 and newer 3500 Cab & Chassis trucks only get the 305 hp (227 kW; 309 PS) and 610 lb⋅ft (827 N⋅m) version of the B6.7, whether it has the Aisin AS68RC or the Mercedes G56 6-speed manual transmission.

As for the 2008 4500/5500 medium duty Chassis Cabs or the Sterling Bullet Trucks, they receive the 350 hp (261 kW; 355 PS) and 610 lb⋅ft (827 N⋅m) version of the B6.7, whether it has the Aisin AS68RC or the Mercedes G56 6-speed manual transmission.

The VG Turbocharger was introduced to reduce turbo lag by adjusting the vanes by sliding a steel ring in the exhaust housing dependent on engine RPM creating more or less pressure inside the exhaust housing and controlling the speed of the turbocharger.

This VGT system has been an extremely common issue with the 6.7 L ISB and is typically diagnosed by the loss of the trucks exhaust brake.

Typically used in marine, agricultural, and construction applications, these engines share many of the same parts as the ISB and utilize the same Bosch fuel system.

[citation needed] In the earlier models of the Cummins B-Series Engine, it was almost entirely mechanical including its fuel system.