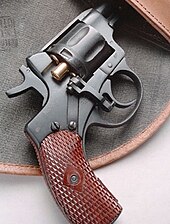

Cylinder (firearms)

In firearms, the cylinder is the cylindrical, rotating part of a revolver containing multiple chambers, each of which is capable of holding a single cartridge.

Each time the gun is cocked, the cylinder indexes by one chamber (for five-chambers, by 72°, for six-chambers, by 60°, for seven-chambers, by 51.43°, for eight-chambers, by 45°, for nine-chambers, by 40°, and for ten-chambers, by 36°).

Serving the same function as a rotary magazine, the cylinder stores ammunitions within the revolver and allows it to fire multiple times, before needing to be reloaded.

Rapid reloading is instead facilitated by the use of a speedloader or moon clip, although these work only on top-break and swing-out cylinder revolvers.

1-1/2 Second Issue revolvers in 1868 with fluted cylinders followed by the Smith & Wesson Model 3 in 1870; thereafter, fluted cylinders were essentially standard on revolvers, including the famous Colt Single Action Army released in 1873 and famously used in the Indian Wars and Wild West.

[6] Oddly enough, the loading gate on the original Colt designs (and copied by nearly all single-action revolvers since) is on the right side, which may favor left-handed users; with the revolver held in the proper grip for shooting in the left hand, the cartridges can easily be ejected and loaded with the right.

In most top-break revolvers, the act of pivoting the barrel and cylinder operates an extractor that pushes the cartridges in the chambers back far enough that they will fall free, or can be removed easily.

The barrel and cylinder are then rotated back and locked in place, and the revolver is ready to fire.

Since the frame is in two parts, held together by a latch on the top rear of the cylinder, top-break revolvers can not handle high pressure or "magnum"-type rounds.

Top-break designs are largely extinct in the world of firearms, but are still commonly found in airguns.

An important feature of all modern designs is an extractor operated by a rod projecting from the front of the cylinder assembly, invented by American gunsmith William Mason in 1865[17] and Italian naval officer Augusto Albini [Wikidata] in 1869.

Reloading the single-shot firearm was time-consuming and in a military or self-defense situation where seconds mattered, this rendered it almost useless after the first shot.

Compared to the single-fire musket, the manufacturing process for this type of firearm was very expensive, which kept their numbers fairly low.

While chemistry was still in its infancy, the development of fulminates as primers for firearm ignition contributed to the invention of the percussion cap.

Percussion caps replaced the flintlock pans as primers and the drilled touch holes were incorporated within nipples.

These arms quickly incorporated mechanisms that automatically rotated the cylinder, aligning the chamber with the barrel, and locking it in place.

[23] It used a long, thin, needle-like firing pin that passed through a small hole at the rear of the cylinder, through the powder, and struck a disposable primer cap that was set behind the bullet.

A revolver using this method had a cylinder with chambers that were bored completely through with a slight channel where the pin rested.

[27] Removal of cartridges from the early models was done one at a time with a push rod as in the pinfire cylinders.

[28] This basically worked the same as a percussion revolver, but with only one nipple that sent the ignition spark to a flash hole at the rear of each chamber.