Deep reactive-ion etching

It was developed for microelectromechanical systems (MEMS), which require these features, but is also used to excavate trenches for high-density capacitors for DRAM and more recently for creating through-silicon vias (TSVs) in advanced 3D wafer level packaging technology.

There is also a physical part, if ions have enough energy, they can knock atoms out of the material to be etched without chemical reaction.

However, during the etching phase, the directional ions that bombard the substrate attack the passivation layer at the bottom of the trench (but not along the sides).

DRIE of glass requires high plasma power, which makes it difficult to find suitable mask materials for truly deep etching.

In DRIE of polymers, Bosch process with alternating steps of SF6 etching and C4F8 passivation take place.

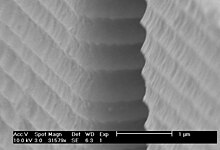

[17] With DRIE it is possible to obtain an aspect ratio of 30 or more,[18] meaning that a surface can be etched with a vertical-walled trench 30 times deeper than its width.

Silicon is lighter and harder than steel, which carries benefits but makes the manufacturing process more challenging.