Dual-mass flywheel

[1] Dual-mass flywheels were developed to address the escalation of torque and power, especially at low revs.

This is where the dual-mass flywheels play a key role, making these mechanical developments more viable.

The wear limit specifications can be found in vehicle or flywheel manufacturer's published documentation.

The softer outer arc spring only acts to increase the problematic resonance frequency range.

This category of bent spring uses the two concepts together: parallel and series connection in order to ensure optimal torsional compensation for each value of torque.

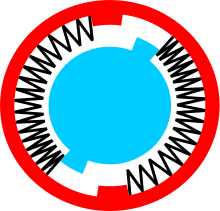

Black: arc springs .

Red: flywheel, crankshaft side

Blue: flywheel, transmission side