Internal combustion engine cooling

For small or special purpose engines, cooling using air from the atmosphere makes for a lightweight and relatively simple system.

Higher-power engines generate more waste heat, but can move more weight, meaning they are generally water-cooled.

Rotary engines have a similar configuration, but the cylinders also continually rotate, creating an air flow even when the vehicle is stationary.

Rotary engines were popular on aircraft until the end of World War I, but had serious stability and efficiency problems.

Engines with higher efficiency have more energy leave as mechanical motion and less as waste heat.

Cooling is also needed because high temperatures damage engine materials and lubricants and becomes even more important in hot climates.

[2] Some high-efficiency engines run without explicit cooling and with only incidental heat loss, a design called adiabatic.

Most liquid-cooled engines use a mixture of water and chemicals such as antifreeze, rust inhibitors, and other additives.

An exception is in a Wankel engine, where some parts of the combustion chamber are never cooled by intake, requiring extra effort for successful operation.

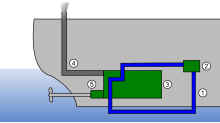

Only the fixed parts of the engine, such as the block and head, are cooled directly by the main coolant system.

High performance engines frequently have additional oil, beyond the amount needed for lubrication, sprayed upwards onto the bottom of the piston just for extra cooling.

In contrast, a liquid-cooled engine might dump heat from the engine to a liquid, heating the liquid to 135 °C (water's standard boiling point of 100 °C can be exceeded as the cooling system is both pressurised, and uses a mixture with antifreeze) which is then cooled with 20 °C air.

In each step, the liquid-cooled engine has half the temperature difference and so at first appears to need twice the cooling area.

Moving heat from the cylinder to a large surface area for air cooling can present problems including difficulties manufacturing the shapes needed for good heat transfer and the space needed for free flow of a large volume of air.

This has an advantage in that it absorbs a great deal of energy with very little rise in temperature (called heat of vaporization), which is good for keeping things cool, especially for passing one stream of coolant over several hot objects and achieving uniform temperature.

However, once water boils, it is an insulator, leading to a sudden loss of cooling where steam bubbles form.

Cooling system regulation includes adjustable baffles in the air flow (sometimes called 'shutters' and commonly run by a pneumatic 'shutterstat'); a fan which operates either independently of the engine, such as an electric fan, or which has an adjustable clutch; and a thermostatic valve or a thermostat that can block the coolant flow when too cool.

Air-cooled diesel engines are chosen for reliability even in extreme heat, because air-cooling would be simpler and more effective at coping with the extremes of temperatures during the depths of winter and height of summer, than water cooling systems, and are often used in situations where the engine runs unattended for months at a time.

Cars and trucks using direct air cooling (without an intermediate liquid) were built over a long period from the very beginning and ending with a small and generally unrecognized technical change.

Before World War II, water-cooled cars and trucks routinely overheated while climbing mountain roads, creating geysers of boiling cooling water.

That was considered normal, and at the time, most noted mountain roads had auto repair shops to minister to overheating engines.

ACS (Auto Club Suisse) maintains historical monuments to that era on the Susten Pass where two radiator refill stations remain.

The spherical bottom was intended to keep it from being set down thus being useless around the house, in spite of which it was stolen, as the picture shows.

Air-cooled engines possibly have an advantage from a thermodynamic point of view due to higher operating temperature.

Because the pump seal leaked mainly when the pump was running and the engine was hot, the water loss evaporated inconspicuously, leaving at best a small rusty trace when the engine stopped and cooled, thereby not revealing significant water loss.

Meanwhile, air cooling advanced in memory of boiling engines even though boil-over was no longer a common problem.

[citation needed] A special class of experimental prototype internal combustion piston engines have been developed over several decades with the goal of improving efficiency by reducing heat loss.

[12] They are generally diesel engines with combustion chamber parts lined with ceramic thermal barrier coatings.

Notice the rows of fins on both the steel cylinder barrel and the aluminum cylinder head. The fins provide additional surface area for air to pass over the cylinder and absorb heat.