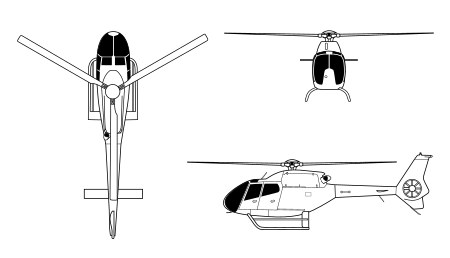

Eurocopter EC120 Colibri

During the 1980s, Aérospatiale sought international partners with which to co-produce the P120, these included aerospace companies in China, Singapore, and Australia.

[8] Under the joint development agreement, Eurocopter received a 61% controlling interest and technical leader in the programme, CATIC received a 24% work share and STAero received a 15% work share; CATIC designed and produced the cabin structure and fuel system, STAero produced the tail boom, access doors, and composite materials, while Eurocopter produced the dynamic assemblies, installed the avionics, electrical and hydraulic systems, and conducted the final assembly activity.

[10] In February 1997, the EC120 Colibri was formally launched at the Helicopter Association International (HAI) show in Anaheim, California; by June 1997, more than 50 orders had been received for the type.

[16] In June 2014, the People's Liberation Army of China became the launch customer for the Harbin-produced HC120, reportedly placing an order for eight of the type with options for fifty more.

Airbus stated they are moving away from the lower end of the market spectrum and those helicopters are not as sophisticated as their traditional product line.

[18] It aimed to reduce pollutant emissions and increase fuel efficiency, nearly double the range and enhance operations in hot and high conditions.

[19] The powerplant trialed was a liquid-cooled, dry sump lubricated 4.6-liter 90° V8 engine with an 1,800-bar (26,000 psi) common rail direct injection, fully machined aluminum blocks, titanium connecting rods, steel pistons and liners, one turbocharger per cylinder bank.

[18] Power was maintained at 2,500 m and ISA+20° and it achieved 42% a fuel consumption reduction, reducing the direct operating costs by 30% along with simpler maintenance.

It incorporates several of Eurocopter's trademarked technologies, those of prominence are the three-bladed Speriflex main rotor head and the eight-bladed fenestron anti-torque tail rotor;[24] these have been partially credited with contributing to the rotorcraft's noise signature, which is 6.7 decibels below International Civil Aviation Organization (ICAO) limits.

[25] According to Airbus Helicopters, the EC120B integrates a high level of advanced technology to make the rotorcraft easier and safer to fly, as well as to reduce costs.

Airbus Helicopter has promoted the type in a training capacity due to features such as positive control response, performance computation systems, modern instrumentation for ease of use, overall compact size, and a high level of cabin visibility.

[25] A wide range of optional equipment can be installed upon the EC120 B, this includes a wire strike protection system, air conditioning, sand filter, skis, windshield wipers, electrical external mirrors, a cargo sling, emergency flotation gear, forward looking infrared (FLIR) cameras, and external spotlights.

In 2004, the United States Department of Homeland Security U.S. Customs and Border Protection (CBP) selected the EC120B to meet its Light Sign Cutter requirement, a program potentially involving 55 aircraft with a total value of US$75 million in then-year dollars.