Extended finite element method

The extended finite element method (XFEM) was developed in 1999 by Ted Belytschko and collaborators,[1] to help alleviate shortcomings of the finite element method and has been used to model the propagation of various discontinuities: strong (cracks) and weak (material interfaces).

The idea behind XFEM is to retain most advantages of meshfree methods while alleviating their negative sides.

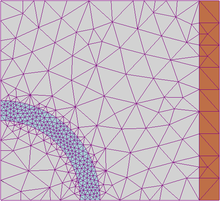

The extended finite element method was developed to ease difficulties in solving problems with localized features that are not efficiently resolved by mesh refinement.

A key advantage of XFEM is that in such problems the finite element mesh does not need to be updated to track the crack path.

It is increasingly being adopted by other commercial finite element software, with a few plugins and actual core implementations available (ANSYS, SAMCEF, OOFELIE, etc.