Flame detector

While capable of detecting fires and explosions within 3–4 milliseconds, a time delay of 2–3 seconds is often included to minimize false alarms which can be triggered by other UV sources such as lightning, arc welding, radiation, and sunlight.

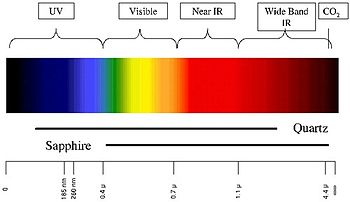

UV detectors typically operate with wavelengths shorter than 300 nm to minimize the effects of natural background radiation.

Multiple channel or pixel array sensors monitoring flames in the near IR band are arguably the most reliable technologies available for detection of fires.

False alarms can be caused by other hot surfaces and background thermal radiation in the area.

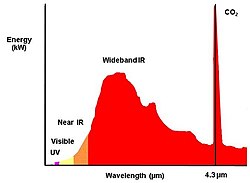

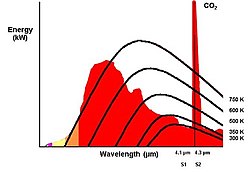

During burning of a hydrocarbon (for example, wood or fossil fuels such as oil and natural gas) much heat and CO2 is released.

However, water vapour, fog or light rain also makes the sensor almost blind, without the user knowing.

The presence of water vapor, fog, or light rain will then also "protect" the monitor causing it to not see the fire.

These detectors are sensitive to both UV and IR wavelengths, and detect flame by comparing the threshold signal of both ranges.

Triple-IR flame detectors compare three specific wavelength bands within the IR spectral region and their ratio to each other.

This allows the detector to distinguish between non-flame IR sources and actual flames which emit hot CO2 in the combustion process.

Thus, one additional UV-C band sensor is sometimes included in flame detectors to add another layer of confirmation, as black-body radiation does not impact UV sensors unless the temperature is extremely high, such as the plasma glow from an Arc welding machine.

IR detectors have often relied on Infrared bulk energy growth to as their primary determining factor for fire detection, declaring an alarm when the sensors exceed a given range and ratio.

alternatively in another design approach, IR-only detectors may only alarm given perfect conditions and clear signal matches, which results in missing the fire when there is too much noise, such as looking into the sunset.

Higher speed sensors allow for not only faster reaction times, but also more data per second, increasing the level of confidence in fire identification, or false alarm rejection.

Furthermore, complex image processing analysis can be executed by computers, which can recognize a flame or even smoke.

Such detectors can be used in large industrial process gas heaters and are connected to the flame control system.

Problems with boilers failing to stay lit can often be due to dirty flame sensors or to a poor burner surface with which to complete the electrical circuit.

[6] Thermocouples are used extensively for monitoring flame presence in combustion heating systems and gas cookers.

A multi-frequency-detector with sensors for UV, visible light, near IR and/or wideband IR thus have much more "sensor data" to calculate with and therefore are able to detect more types of fires and to detect these types of fires better: hydrogen, methanol, ether or sulphur.

Not all manufacturers of flame detectors use sharp filters for the 4.3 μm radiation and thus still pick up quite an amount of sunlight.

The big economical advantage is that detector windows can be made of quartz instead of expensive sapphire.

These electro-optical sensor combinations also enable the detection of non-hydrocarbons like hydrogen fires without the risk of false alarms caused by artificial light or electrical welding.

Dual- or multi-infrared detectors suppress the effects of heat radiation by means of sensors which detect just off the CO2 peak; for example at 4.1 μm.

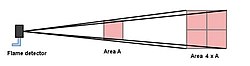

For some applications the flame detector needs to be aligned precisely to take care that it does not detect potential background radiation sources.

A high sensitivity on the edges of the angle of vision provides advantages for the projection of a flame detector.

A rule of thumb is, that the mounting height of the flame detector is twice as high as the highest object in the field of view.

A "roof" on top of the flame detector (30 x 30 cm, 1 x 1-foot) prevents quick pollution in outdoor applications.

The range of flame detectors to the 30 x 30 cm, 1 x 1-foot industry standard fire is stated within the manufacturers data sheets and manuals, this range can be affected by the previously stated de-sensitizing effects of sunlight, water, fog, steam and blackbody radiation.

At long distances other parameters are playing a significant part; like the occurrence of water vapour and of cold CO2 in the air.