Flying shuttle

Formerly, a broad-cloth loom necessitated the presence of a weaver on each side, but with the advent of the flying shuttle, a solitary operator could handle the task proficiently.

The widespread adoption of the flying shuttle by the 1750s dramatically exacerbated this labour imbalance, marking a notable shift in textile production dynamics.

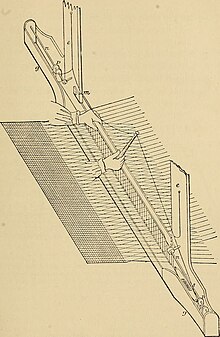

In a typical frame loom, as used previous to the invention of the flying shuttle, the operator sat with the newly woven cloth before them, using treadles or some other mechanism to raise and lower the heddles, which opened the shed in the warp threads.

More importantly, the coordination between the throwing and catching of the shuttle required that the weaver was weaving narrow cloth (typically 60 inches (150 cm) or less).

It is often incorrectly written that Kay was attacked and fled to France, but in fact he simply moved there to attempt to rent out his looms, a business model that had failed him in England.

[5] The flying shuttle produced a new source of injuries to the weaving process; if deflected from its path, it could be shot clear of the machine, potentially striking and injuring workers.