Food irradiation

[4] The U.S. Food and Drug Administration (FDA), the World Health Organization (WHO), the Centers for Disease Control and Prevention (CDC), and U.S. Department of Agriculture (USDA) have performed studies that confirm irradiation to be safe.

[11][12][13][14][15] Irradiation is used to reduce or eliminate pests and the risk of food-borne illnesses as well as prevent or slow spoilage and plant maturation or sprouting.

Depending on the dose, some or all of the organisms, microorganisms, bacteria, and viruses present are destroyed, slowed, or rendered incapable of reproduction.

This is useful for people at high risk of infection in hospitals as well as situations where proper food storage is not feasible, such as rations for astronauts.

[17] Pests such as insects have been transported to new habitats through the trade in fresh produce and significantly affected agricultural production and the environment once they established themselves.

[19][20] The higher doses required to destroy pests are not used due to either affecting the look or taste, or cannot be tolerated by fresh produce.

The higher the likelihood of these collisions over a distance are, the lower the penetration depth of the irradiation process is as the energy is more quickly depleted.

When the process damages DNA or RNA, effective reproduction becomes unlikely halting the population growth of viruses and organisms.

Because chemical agents do not provide efficient microbial reductions, watercress has been tested with gamma irradiation treatment in order to improve both safety and the shelf life of the product.

[31] It is traditionally used on horticultural products to prevent sprouting and post-packaging contamination, delay post-harvest ripening, maturation and senescence.

[5] Endpoints include subchronic and chronic changes in metabolism, histopathology, function of most organs, reproductive effects, growth, teratogenicity, and mutagenicity.

[citation needed] For some forms of treatment, packaging is used to ensure the food stuffs never come in contact with radioactive substances[34] and prevent re-contamination of the final product.

Special precautions are taken to ensure the food stuffs never come in contact with the radioactive substances and that the personnel and the environment are protected from radiation exposure.

[26] Cobalt-60 is the most common source of gamma rays for food irradiation in commercial scale facilities as it is water-insoluble and hence has little risk of environmental contamination by leakage into the water systems.

[38] The special trucks must meet high safety standards and pass extensive tests to be approved to ship radiation sources.

An incident where water-soluble caesium-137 leaked into the source storage pool requiring NRC intervention[39] has led to near elimination of this radioisotope.

In most designs, the radioisotope, contained in stainless steel pencils, is stored in a water-filled storage pool which absorbs the radiation energy when not in use.

For treatment, the source is lifted out of the storage tank, and product contained in totes is passed around the pencils to achieve required processing.

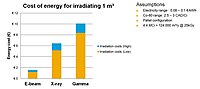

The high power correlates with a higher throughput and lower unit cost, but electron beams have low dose uniformity and a penetration depth of centimeters.

[citation needed] X-rays are produced by bombardment of dense target material with high-energy accelerated electrons (this process is known as bremsstrahlung-conversion), giving rise to a continuous energy spectrum.

Tantalum is usually preferred over tungsten for industrial, large-area, high-power targets because it is more workable than the latter and has a higher threshold energy for induced reactions.

Regardless of treatment source, all processing facilities must adhere to safety standards set by the International Atomic Energy Agency (IAEA), Codex Code of Practice for the Radiation Processing of Food, Nuclear Regulatory Commission (NRC), and the International Organization for Standardization (ISO).

Irradiation facilities are designed with overlapping layers of protection, interlocks, and safeguards to prevent accidental radiation exposure.

The suggested rules for labeling is published at CODEX-STAN – 1 (2005),[52] and includes the usage of the Radura symbol for all products that contain irradiated foods.

The European Union does not provide for the use of the Radura logo and relies exclusively on labeling by the appropriate phrases in the respective languages of the Member States.

The lack of packaging material approval limits manufacturers production and expansion of irradiated prepackaged foods.

Each food approved for irradiation has specific guidelines in terms of minimum and maximum dosage as determined safe by the FDA.

Presently, Belgium, Czech Republic, France, Italy, Netherlands, and Poland allow the sale of many different types of irradiated foods.

In 2021 the most common food items irradiated were frog legs at 65.1%, poultry 20.6% and dried aromatic herbs, spices and vegetables seasoning.

The regulators enforce a safety culture that mandates that all incidents that occur are documented and thoroughly analyzed to determine the cause and improvement potential.