Fostoria Glass Company

They started their company in northwest Ohio to take advantage of newly discovered natural gas that was an ideal fuel for glassmaking.

During the 1970s, foreign competition and changing preferences forced the company to make substantial investments in cost-saving automation technology.

Management at Wheeling's J. H. Hobbs, Brockunier and Company had a policy of using skilled glassworkers from Europe, who would train the local employees—resulting in a superior workforce.

Waterways provided an efficient and safe way to transport glass, especially before the construction of high-quality roads and the railroad system.

Allegheny County, Pennsylvania, (which includes Pittsburgh) was the nation's leading glass producer based on value of production.

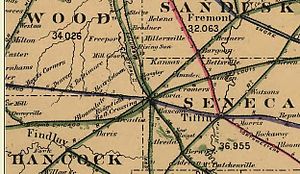

[10] In early 1886, a major discovery of natural gas occurred near the small village of Findlay, Ohio.

[11] Communities in northwestern Ohio began using low-cost natural gas along with free land and cash to entice glass companies to start operations in their town.

The plant was located on Fostoria's South Vine Street and the town was served by multiple railroads.

[19] Former Ohio governor Charles Foster, son of the city of Fostoria's namesake, was added to this group of glass industry veterans to form the new company's board of directors.

[23] The company advertised as a manufacturer of pressed glassware, and specialties were candle stands, candelabras, and banquet lamps.

A popular early pattern called Cascade looked like a swirl and was used for candelabras and ink wells.

Among them was Charles E. Beam, who was the head of the company's mold shop and eventually added to the board of directors.

[27] Beam received a patent in 1890 for a glass mold that would enable pieces of chandeliers and candelabras to have small holes.

[28] Company president Martin was also a talented designer, and he patented the Cascade ink well (called an inkstand) in 1890 and a paper weight with swirl sides in 1891.

[31] Fostoria's Valencia pattern, number 205, is often called Artichoke because of the shape of the overlapping leaves on the bottom half of the glassware.

Its appearance has a strong resemblance to a French company's pattern, and Fostoria Glass had some employees from France's glassmaking region.

During April 1891, Fostoria Glass executives decided to move to Moundsville, West Virginia, because of the availability of coal as a fuel for the plant—and $10,000 cash (equivalent to $339,111 in 2023) offered by the community.

[39] In early December, the move to Moundsville was delayed by a restraining order when several members of the Crimmel family, who owned stock in the company, filed suit.

The Dalzell brothers had been involved with the glass business as owners and management in West Virginia and Ohio.

[63] From the beginning of the Moundsville operations until about 1915, Fostoria focused on oil lamps and products for restaurants and bars—especially stemware and tumblers.

[67] Prohibition diminished the market for commercial barware, causing Fostoria to put more emphasis on tableware for the home.

This led to low cost dinner sets being made by injecting molten glass into an automated pressing mold.

The product often had minor flaws, so "lacy" patterns were often included in the mold, or etched onto the glass, to hide imperfections.

[64] During the Great Depression the company made glassware for the higher and lower cost segments of the market.

A combination of quality products and national advertising helped the company continue to be the largest manufacturer of handmade glassware in the United States.

[81] In the 1960s and 1970s, the company's marketing campaign expanded to include boutiques and display rooms within jewelry and department stores.

First Lady Jacqueline Kennedy had chosen Morgantown glassware for official White House tableware, and Fostoria sought to capitalize on this.

This segment was profitable for Fostoria for only two years, as department stores eliminated secondary sources and restaurants began switching to machine-made glass.

"[21] During the 1970s, changing preferences and a substantial increase in imports of machine-made lead-crystal tableware forced the company to make significant investments in machinery.

This late attempt to be more competitive by automating more of the manufacturing process unsettled the labor force, and the company faced strikes during the early 1970s.