Friction drive

The simplest form of friction drive is a pair of cylinders mounted on parallel axes, pressing against each others.

[6] Another important type of friction drive consists of a wheel rolling over a mostly flat surface or mostly straight track.

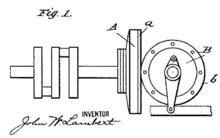

Another important type of friction drive consists of two discs with perpendicular axes, arranged so that the edge of one wheel presses against the flat face of the other.

This speed mismatch causes considerable friction at the edges of the first disk, wearing it out and wasting mechanical power as heat.

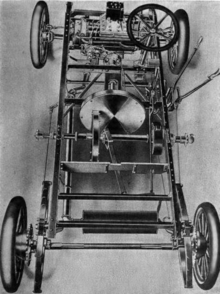

Automobiles using this drive system included the Anglo-Dane, the Arista, the Armadale, the Astra, the Allvelo, the Bukh & Gry, the Cartercar, the Crown 12HP Model Two (1905-1906), the Davis Totem, the G.W.K., the Kelsey, the Lambert, the LuLu, the Metz, the Ner-a Car, the Richardson, and the Turicum.

The Turicum's friction drive consisted of a flat steel disk coupled directly to the engine.

This primary disk subsequently drove a smaller leather covered wheel oriented normal to its surface.

The first is that the amount of torque that can be transferred is a function of the area of the contact patch between the two members and the pressure applied to it by the two parts.

They also accumulate small amounts of slippage in normal operation because local deformation of the surface changes the effective radius of the part.