Wood finishing

Wood finishing refers to the process of refining or protecting a wooden surface, especially in the production of furniture where typically it represents between 5 and 30% of manufacturing costs.

[1][2] Finishing is the final step of the manufacturing process that gives wood surfaces desirable characteristics, including enhanced appearance and increased resistance to moisture and other environmental agents.

Finishing can also make wood easier to clean[3] and keep it sanitized, sealing pores that can be breeding grounds for bacteria.

Finishing can also influence other wood properties, for example tonal qualities of musical instruments and hardness of flooring.

[4][5] In addition, finishing provides a way of giving low-value woods the appearance of ones that are expensive and difficult to obtain.

[6] Care should be taken to ensure that edges of furniture are rounded so they can be adequately coated and are able to resist wear and cracking.

Careful attention should also be given to the design and strength of wooden joints to ensure they do not open-up in service and crack the overlying finish.

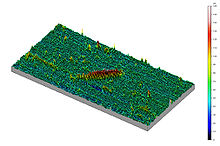

[10][11] Woods that are coarse textured such as oaks and other ring-porous hardwoods may need to be filled before they are finished to ensure the coating can bridge the pores and resist cracking.

[7] Some tropical woods, such as rosewood (Dalbergia nigra), cocobolo (Dalbergia retusa) and African padauk (Pterocarpus soyauxii), contain extractives such as quinones, which retard the curing of unsaturated polyester and UV-cured acrylate coatings, and so other finishing systems should be used with these species.

Both problems can be avoided by storing wood indoors in an environment where it can equilibriate to a recommended moisture content (6 to 8%) that is similar to that of the intended end use of the furniture.

[7] These defects include cutter marks and burns, scratches and indentations, small glue spots and raised grain.

[19] Larger defects that interfere with wood finishing include dent, gouges, splits and glue spots and smears.

The transfer of heat from the iron to the wood will cause compressed fibres in the dent to recover their original dimensions.

Sub-surface glue will reduce the absorption of stain by wood, and may alter the scratch pattern created by sanding.

[27] Wood can be stained to change its colour or left unstained before application of lacquer, or other types of top-coats.

Pigmented stains tend to highlight the grain (and also sanding scratches), whereas dyes do not have this effect and are more transparent.

For this reason, as pointed out by Flexner, many people prefer to omit the staining step when finishing wood.

Finally, the surface may be polished or buffed using steel wool, pumice, rotten stone or other materials, depending on the shine desired.

Often, a final coat of wax is applied over the finish to add a degree of protection.

Choosing a clear finish for wood involves trade-offs between appearance, protection, durability, safety, requirements for cleaning, and ease of application.

These systems consist of a series of processing stations that may include sanding, dust removal, staining, sealer and topcoat applications.

The hangline approach to automated wood finishing also allows the option of moving items up to warmer air at the ceiling level to speed up drying process.

The towline approach to automating wood finishing uses mobile carts that are propelled by conveyors mounted in or on the floor.

The mobile carts used in the towline approach can be designed with top platens that rotate either manually or automatically.