Gas lift

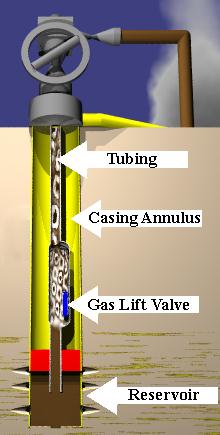

Gas may be injected continuously or intermittently, depending on the producing characteristics of the well and the arrangement of the gas-lift equipment.

[1] The amount of gas to be injected to maximize oil production varies based on well conditions and geometries.

The newest way is using risk-optimization which considers all aspects for gas lift allocation.

These systems used single point injection of air into the liquid stream, normally through a foot valve at the bottom of the string.

From 1929 until 1945 about 25000 patents were issued on different types of gas lift valves that could be used for unloading in stages.

[4] Some of these systems involved moving the tubing, or using wireline sinker bars to change the lift point.

In 1951 the sidepocket mandrel was developed for selectively positioning and retrieving gas lift valves with wireline.