Generation IV reactor

Moir and Teller consider the molten-salt reactor, a less developed technology, as potentially having the greatest inherent safety of the six models.

It was connected to the grid in December 2023, making it the world's first Gen IV reactor to enter commercial operation.

[9][10][11] In 2024, it was reported that China would also build the world’s first thorium molten salt nuclear power station, scheduled to be operational by 2029.

[12] The Generation IV International Forum (GIF) is an international organization with its stated goal being "the development of concepts for one or more Generation IV systems that can be licensed, constructed, and operated in a manner that will provide a competitively priced and reliable supply of energy ... while satisfactorily addressing nuclear safety, waste, proliferation and public perception concerns.

[2] It has been instrumental in coordinating research into the six types of Generation IV reactors, and in defining the scope and meaning of the term itself.

[19] In May 2019, Terrestrial Energy, the Canadian developer of a molten salt reactor, became the first private company to join GIF.

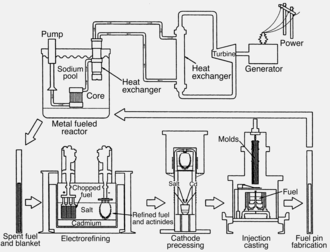

Fast reactors offer the possibility of burning actinides to further reduce waste and can breed more fuel than they consume.

These systems offer significant advances in sustainability, safety and reliability, economics, proliferation resistance, and physical protection.

The very-high-temperature reactor (VHTR) uses a graphite-moderated core with a once-through uranium fuel cycle, using helium or molten salt.

In 2012, as part of its next generation nuclear plant competition, Idaho National Laboratory approved a design similar to Areva's prismatic block Antares reactor to be deployed as a prototype by 2021.

[22] In January 2016, X-energy was provided a five-year grant of up to $40 million by the United States Department of Energy to advance their reactor development.

[26] Since 2021, the Chinese government is operating a demonstration HTR-PM 200-MW high temperature pebble bed reactor as a successor to its HTR-10.

This concept mixes the liquid natural uranium and molten chloride coolant in the reactor core, reaching very high temperatures at atmospheric pressure.

Conventionally only fast spectrum reactors have been considered viable for utilization or reduction of the spent nuclear fuel.

SCWRs are basically light water reactors (LWR) operating at higher pressure and temperatures with a direct, once-through heat exchange cycle.

It is built upon two proven technologies, LWRs, the most commonly deployed power generating reactors, and superheated fossil fuel fired boilers, also in wide use.

Fast reactors can be configured to "burn", or fission, all actinides, and given enough time, therefore drastically reduce the actinides fraction in spent nuclear fuel produced by the present world fleet of thermal neutron light water reactors, thus closing the fuel cycle.

These NPPs are being used to provide operating experience and technological solutions that will be applied to the construction of the BN-1200 (OKBM Afrikantov first Gen IV reactor).

In September 2002, fuel burn up efficiency in the FBTR for the first time reached the 100,000 megawatt-days per metric ton uranium (MWd/MTU) mark.

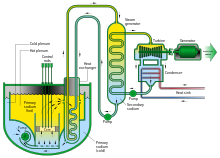

SFR fuel expands when the reactor overheats, automatically slowing down the chain reaction, making it passively safe.

The use of liquid metal instead of water as coolant allows the system to work at atmospheric pressure, reducing the risk of leakage.

The design reduces the half lives of the fissionable elements present in spent nuclear fuel while generating electricity largely as a byproduct.

The lead-cooled fast reactor (LFR)[27] features a fast-neutron-spectrum lead or lead/bismuth eutectic (LBE) coolant with a closed fuel cycle.

The European Sustainable Nuclear Industrial Initiative is funding a 100 MWt LFR, an accelerator-driven sub-critical reactor called MYRRHA.

[49] Using lead or molten salt coolants mitigates this problem as they are less reactive and have a high freezing temperature and ambient pressure.

For example, the reactors at Fort St. Vrain Generating Station and HTR-10 are similar to the proposed Gen IV VHTR designs, and the pool type EBR-II, Phénix, BN-600 and BN-800 reactor are similar to the proposed pool type Gen IV SFR designs.

Nuclear engineer David Lochbaum cautions, "the problem with new reactors and accidents is twofold: scenarios arise that are impossible to plan for in simulations; and humans make mistakes".

[50] As one director of a U.S. research laboratory put it, "fabrication, construction, operation, and maintenance of new reactors will face a steep learning curve: advanced technologies will have a heightened risk of accidents and mistakes.