Ground (electricity)

Connecting exposed conductive parts to a "ground" wire which provides a low-impedance path for current to flow back to the incoming neutral (which is also connected to ground, close to the point of entry) will allow circuit breakers (or RCDs) to interrupt power supply in the event of a fault.

Connection to ground also limits the build-up of static electricity when handling flammable products or electrostatic-sensitive devices.

An electrical ground system should have an appropriate current-carrying capability to serve as an adequate zero-voltage reference level.

In electronic circuit theory, a "ground" is usually idealized as an infinite source or sink for charge, which can absorb an unlimited amount of current without changing its potential.

Stray voltages or earth potential rise effects will occur, which may create noise in signals or produce an electric shock hazard if large enough.

Long-distance electromagnetic telegraph systems from 1820 onwards[a] used two or more wires to carry the signal and return currents.

However, there were problems with this system, exemplified by the transcontinental telegraph line constructed in 1861 by the Western Union Company between St. Joseph, Missouri, and Sacramento, California.

In the late nineteenth century, when telephony began to replace telegraphy, it was found that the currents in the earth induced by power systems, electric railways, other telephone and telegraph circuits, and natural sources including lightning caused unacceptable interference to the audio signals, and the two-wire or 'metallic circuit' system was reintroduced around 1883.

This is especially important in bathrooms where one may be in contact with several different metallic systems such as supply and drain pipes and appliance frames.

Alternatively, some amount of electrical impedance may be connected between the distribution system and ground, to limit the current that can flow to earth.

Low resistance grounding systems will have a time rating (say, 10 seconds) that indicates how long the resistor can carry the fault current before overheating.

[7] Where the danger of electric shock is high, special ungrounded power systems may be used to minimize possible leakage current to ground.

On wet construction sites or in shipyards, isolation transformers may be provided so that a fault in a power tool or its cable does not expose users to shock hazard.

This gradient creates a hazard to anyone standing on the earth in an area of the electrical substation that is insufficiently insulated from ground.

This problem is alleviated by creating a low-impedance equipotential bonding plane installed in accordance with IEEE 80, within the substation.

Some devices require a connection to the mass of earth to function correctly, as distinct from any purely protective role.

To avoid accidents, such functional grounds are normally wired in white, cream or pink cable, and not green or green/yellow.

The electrical safety ground (2) was discussed in previous sections and is unsuitable for radio purposes, although required for the power supply.

Medium to high power transmitters usually have an extensive ground system consisting of bare copper cables buried in the earth under the antenna, to lower resistance.

[14] For AM broadcast band antennas this requires a circular land area extending from the mast 47–136 meters (154–446 ft).

In the LF and VLF bands, construction height limitations require that electrically short antennas be used, shorter than the fundamental resonant length of one quarter of a wavelength (

The large area is required to dissipate the high current of a lightning strike without damaging the system conductors by excess heat.

In an electrical substation a ground (earth) mat is a mesh of conductive material installed at places where a person would stand to operate a switch or other apparatus; it is bonded to the local supporting metal structure and to the handle of the switchgear, so that the operator will not be exposed to a high differential voltage due to a fault in the substation.

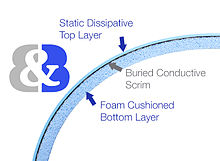

A static dissipative mat that rests on a conductive surface (commonly the case in military facilities) are typically made of 3 layers (3-ply) with static dissipative vinyl layers surrounding a conductive substrate which is electrically attached to ground (earth).

Conductive mats are made of carbon and used only on floors for the purpose of drawing static electricity to ground as quickly as possible.

[17] In computer repair shops and electronics manufacturing, workers must be grounded before working on devices sensitive to voltages capable of being generated by humans.

It is frequently used with low-power consumer devices, and when engineers, hobbyists, or repairmen are working on circuits that would normally be operated using the power line voltage.

In the past, grounded appliances have been designed with internal isolation to a degree that allowed the simple disconnection of ground by cheater plugs without apparent problem (a dangerous practice, since the safety of the resulting floating equipment relies on the insulation in its power transformer).

If the ground is disconnected by a cheater plug or by accident, the resulting leakage current can cause mild shocks, even without any fault in the equipment.

[20] Class II appliances and power supplies (such as cell phone chargers) do not provide any ground connection, and are designed to isolate the output from input.