Hafnium

Its existence was predicted by Dmitri Mendeleev in 1869, though it was not identified until 1922, by Dirk Coster and George de Hevesy.

Some semiconductor fabrication processes use its oxide for integrated circuits at 45 nanometers and smaller feature lengths.

Hafnium's large neutron capture cross section makes it a good material for neutron absorption in control rods in nuclear power plants, but at the same time requires that it be removed from the neutron-transparent corrosion-resistant zirconium alloys used in nuclear reactors.

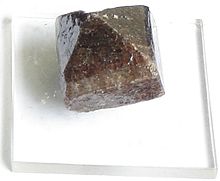

Hafnium is a shiny, silvery, ductile metal that is corrosion-resistant and chemically similar to zirconium[12] in that they have the same number of valence electrons and are in the same group.

Also, their relativistic effects are similar: The expected expansion of atomic radii from period 5 to 6 is almost exactly canceled out by the lanthanide contraction.

As a consequence of lanthanide contraction, the chemistry of hafnium and zirconium is so similar that the two cannot be separated based on differing chemical reactions.

The melting and boiling points of the compounds and the solubility in solvents are the major differences in the chemistry of these twin elements.

[15][18] The extinct radionuclide 182Hf has a half-life of 8.9±0.1 million years, and is an important tracker isotope for the formation of planetary cores.

A potential source of hafnium is trachyte tuffs containing rare zircon-hafnium silicates eudialyte or armstrongite, at Dubbo in New South Wales, Australia.

[26] The methods first used—fractional crystallization of ammonium fluoride salts[27] or the fractional distillation of the chloride[28]—have not proven suitable for an industrial-scale production.

[30] The purified hafnium(IV) chloride is converted to the metal by reduction with magnesium or sodium, as in the Kroll process.

[33] Hafnium and zirconium tend to occur together in nature and the similarity of their ionic radii makes their chemical separation rather difficult.

In his report on The Periodic Law of the Chemical Elements, in 1869, Dmitri Mendeleev had implicitly predicted the existence of a heavier analog of titanium and zirconium.

[37] The X-ray spectroscopy done by Henry Moseley in 1914 showed a direct dependency between spectral line and effective nuclear charge.

This led to the nuclear charge, or atomic number of an element, being used to ascertain its place within the periodic table.

In 1914, several people claimed the discovery after Henry Moseley predicted the gap in the periodic table for the then-undiscovered element 72.

[41] The controversy was partly because the chemists favored the chemical techniques which led to the discovery of celtium, while the physicists relied on the use of the new X-ray spectroscopy method that proved that the substances discovered by Urbain did not contain element 72.

[44][45] These suggestions were based on Bohr's theories of the atom which were identical to chemist Charles Bury,[42] the X-ray spectroscopy of Moseley, and the chemical arguments of Friedrich Paneth.

[53][54][55] Today, the Faculty of Science of the University of Copenhagen uses in its seal a stylized image of the hafnium atom.

[56] Hafnium was separated from zirconium through repeated recrystallization of the double ammonium or potassium fluorides by Valdemar Thal Jantzen and von Hevesey.

An alloy used for liquid-rocket thruster nozzles, for example the main engine of the Apollo Lunar Modules, is C103 which consists of 89% niobium, 10% hafnium and 1% titanium.

[66][67][68] Hafnium-based compounds are employed in gates of transistors as insulators in the 45 nm (and below) generation of integrated circuits from Intel, IBM and others.

[69][70] Hafnium oxide-based compounds are practical high-k dielectrics, allowing reduction of the gate leakage current which improves performance at such scales.

This program eventually concluded that using the above-mentioned 178m2Hf nuclear isomer of hafnium to construct high-yield weapons with X-ray triggering mechanisms—an application of induced gamma emission—was infeasible because of its expense.

A pyridyl-amidohafnium catalyst can be used for the controlled iso-selective polymerization of propylene which can then be combined with polyethylene to make a much tougher recycled plastic.

The National Institute for Occupational Safety and Health (NIOSH) has set the same recommended exposure limit (REL).