Heat exchanger

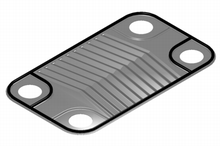

The exchanger's performance can also be affected by the addition of fins or corrugations in one or both directions, which increase surface area and may channel fluid flow or induce turbulence.

On one hand, these heat exchangers are cheap for both design and maintenance, making them a good choice for small industries.

This configuration is preferable when the two fluids are intended to reach exactly the same temperature, as it reduces thermal stress and produces a more uniform rate of heat transfer.

This configuration is preferable when the objective is to maximize heat transfer between the fluids, as it creates a larger temperature differential when used under otherwise similar conditions.

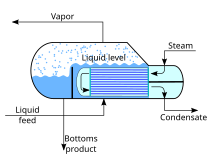

The word steam generator was regularly used to describe a boiler unit where a hot liquid stream is the source of heat rather than the combustion products.

These exchangers are composed of many thin, slightly separated plates that have very large surface areas and small fluid flow passages for heat transfer.

A pillow plate heat exchanger is commonly used in the dairy industry for cooling milk in large direct-expansion stainless steel bulk tanks.

On the liquid side of these heat exchangers, the common fluids are water, a water-glycol solution, steam, or a refrigerant.

The introduction of indentations placed within the heat exchange fins controlled condensation, allowing water molecules to remain in the cooled air.

A cracked heat exchanger is therefore a dangerous situation that requires immediate attention because combustion products may enter living space.

This attribute is often leveraged and partially reallocated to gain other improvements in performance, according to well known tradeoffs in heat exchanger design.

Once the main spiral pack has been rolled, alternate top and bottom edges are welded and each end closed by a gasketed flat or conical cover bolted to the body.

"[citation needed] They are also easily cleaned, opening out like an oven where any buildup of foulant can be removed by pressure washing.

Self-cleaning water filters are used to keep the system clean and running without the need to shut down or replace cartridges and bags.

As such, heat exchangers are most often selected via computer programs, either by system designers, who are typically engineers, or by equipment vendors.

Though cost is often the primary criterion, several other selection criteria are important: Small-diameter coil technologies are becoming more popular in modern air conditioning and refrigeration systems because they have better rates of heat transfer than conventional sized condenser and evaporator coils with round copper tubes and aluminum or copper fin that have been the standard in the HVAC industry.

Small diameter coils can withstand the higher pressures required by the new generation of environmentally friendlier refrigerants.

Two small diameter coil technologies are currently available for air conditioning and refrigeration products: copper microgroove[31] and brazed aluminum microchannel.

Typically in the manufacturing industry, several differing types of heat exchangers are used for just one process or system to derive the final product.

With sufficient knowledge of heat exchanger types and operating requirements, an appropriate selection can be made to optimise the process.

Integrity inspection of plate and tubular heat exchanger can be tested in situ by the conductivity or helium gas methods.

Mechanical integrity monitoring of heat exchanger tubes may be conducted through Nondestructive methods such as eddy current testing.

[33] The precipitation of insoluble asphaltenes in crude preheat trains has been successfully modeled as a first order reaction by Ebert and Panchal[34] who expanded on the work of Kern and Seaton.

To prevent fouling, designers typically ensure that cooling water velocity is greater than 0.9 m/s and bulk fluid temperature is maintained less than 60 °C (140 °F).

In species that have external testes (such as human), the artery to the testis is surrounded by a mesh of veins called the pampiniform plexus.

"Countercurrent" heat exchangers occur naturally in the circulatory systems of fish, whales and other marine mammals.

Heat exchangers are also present in the tongues of baleen whales as large volumes of water flow through their mouths.

[44] Estimated at US$17.5 billion in 2021, the global demand of heat exchangers is expected to experience robust growth of about 5% annually over the next years.

With an expanding desire for environmentally friendly options and increased development of offices, retail sectors, and public buildings, market expansion is due to grow.

By Newton's law of cooling the rate of change in energy of a small volume of fluid is proportional to the difference in temperatures between it and the corresponding element in the other pipe: ( this is for parallel flow in the same direction and opposite temperature gradients, but for counter-flow heat exchange countercurrent exchange the sign is opposite in the second equation in front of