Braiding machine

A braiding machine is a device that interlaces three or more strands of yarn or wire to create a variety of materials, including rope, reinforced hose, covered power cords, and some types of lace.

[1][2] Braiding materials include natural and synthetic yarns, metal wires, leather tapes, and others.

This enables large stiff braided cables to be output horizontally, which eliminates the need for factory buildings with tall ceilings.

Braiding machines, although they have an apparent complex movement of bobbins, are mechanically simple and robust.

This enables factories with hundreds of machines to be operated by just a few workers, which reduces cost of labor and makes products cheaper and/or profits higher.

[4] They were well suited to be driven by the steam engines of the industrial revolution and electric motor-powered machines were common by the beginning of the 20th century.

Each ribbon is held by one person, and the group of people form a ring about the base of the pole.

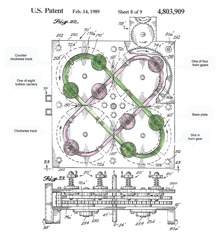

A square braider uses a grid of gears and intersecting tracks to produce a solid-core braid.

The speed of a horn gear braider is limited by the effort needed to force bobbin carriers to follow a serpentine path.