Hydronics

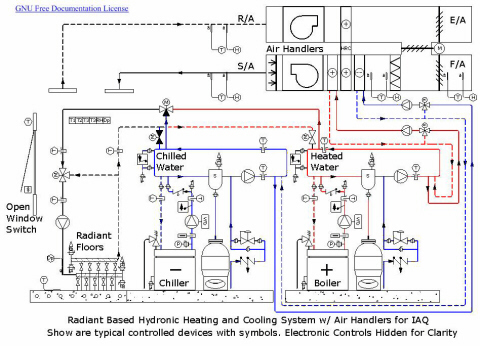

A recent innovation is the chiller boiler system, which provides an efficient form of HVAC for homes and smaller commercial spaces.

If positioned correctly a radiator will create an air convection current in the room, which will provide the main heat transfer mechanism.

These systems depend on the proper operation of thermostatic air-venting valves located on radiators throughout the heated area.

When a heating cycle begins, the boiler produces steam, which expands and displaces the air in the system.

[citation needed] In two-pipe steam systems, there is a return path for the condensate and it may involve pumps as well as gravity-induced flow.

Because of this, it is always recommended to: minimize the distribution piping pressure drops; use a pump with a flat head characteristic[when defined as?

], include balancing and flow-measuring devices at each terminal or branch circuit; and use control valves with a high head loss[when defined as?]

There have been considerable improvements in the efficiency and therefore the operating costs of a hydronic heating system with the introduction of insulating products.

Radiator Panel system pipes are covered with a fire rated, flexible and lightweight elastomeric rubber material designed for thermal insulation.

Slab Heating efficiency is improved with the installation of a thermal barrier made of foam.

This involves measuring and setting the flow to achieve an optimal distribution of energy in the system.

Air causes irritating system noises, and interrupts proper heat transfer to and from the circulating fluids.

In addition, unless reduced below an acceptable level, the oxygen dissolved in water causes corrosion.

Over time these particles can become loose and travel around the pipes, reducing or even blocking the flow as well as damaging pump seals and other components.

The expansion tank accommodates the expanded water by further air compression and helps maintain a roughly constant pressure in the system across the expected change in fluid volume.

At least one combination over-temperature and over-pressure relief valve is always fitted to the system to allow the steam or water to vent to the atmosphere in case of the failure of some mechanism (such as the boiler temperature control) rather than allowing the catastrophic bursting of the piping, radiators, or boiler.

Proper design and the addition of vacuum breakers reduce or eliminate the risk of these problems.