J. H. Hobbs, Brockunier and Company

J. H. Hobbs, Brockunier and Company was one of the largest and best-known manufacturers of glass in the United States during the 19th century.

Both men held supervisory positions at the New England Glass Company in Massachusetts before starting their business venture.

The firm was reorganized multiple times during the 50 years following 1845, but members of the Hobbs family were always part of the ownership.

[8][Note 2] The United States Embargo Act of 1807, and the War of 1812, made red lead extremely difficult to acquire.

After the war England kept the price of red lead high, and dumped low–priced glass products in the United States.

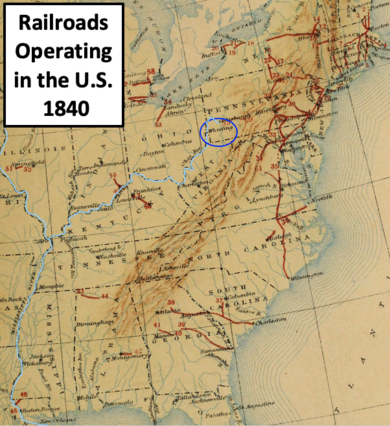

[7] Glassmaking on the East Coast of the United States peaked around 1850, as plants shifted to Pittsburgh because of the availability of coal for fuel.

[15] By 1850, the United States had 3,237 free men above age 15 who listed their occupation as part of the glass manufacturing process.

[33] An attempt by Horatio Miller (without Plunkett) to keep the factory producing ended in late 1842 with another default, which caused the plant to be closed.

[36] In 1845, James B. Barnes and John L. Hobbs moved to the Ohio River community of Ritchietown to start a new glass company.

[41] The elder Barnes and Hobbs had worked in supervisory positions at the New England Glass Company in Massachusetts.

[43] Among the initial products were lantern chimneys (the glass surrounding the flame), jars, tumblers, and cologne bottles.

It is probable that profits from the Wood County oil venture enabled Brockunier and John H. Hobbs to buy stakes in the South Wheeling glassmaking firm.

[56] The stated purpose of the new firm was "manufacturing Flint and Fancy Colored Glassware, in all its branches, at the Works, South Wheeling.

[55] Under the management J. H. Hobbs, Brockunier and Company the next twenty-five years were a golden era for the South Wheeling glassworks.

He began testing various combinations of ingredients to make high quality glass without lead, but his experiments were not successful.

[46] In the fall of the same year, chemist William Leighton Sr. joined the firm as a partner, and continued the experiments with lime glass.

[62] This improvement in the formula for glass was considered one of two great advances in American glassmaking during the 19th century, the other being the invention of pressing.

[66] Two other important innovations made by the company were: (1) the use of benzine in the polishing furnace, which eliminates sulfur that can cloud the glass; and (2) applying cold air to chill molds.

[67] By 1873 the South Wheeling Glass Works belonging to J. H. Hobbs, Brockunier and Company occupied 400 feet (121.9 m) square, and had three furnaces with a combined capacity of 29 pots.

[70] While 1880 statistics are not readily available for J. H. Hobbs, Brockunier and Company, an 1879 article (as stated earlier) mentioned it had 350 employees and revenue of $300,000.

[73] The glassworks was shipping about 400 railroad carloads per year to points in the United States, Cuba, South America, Australia, and Europe.

[77] Glass companies sought to capitalize on the Morgan Vase publicity by producing products that looked similar.

[96] In the 19th century, the various versions of the Hobbs glass works had a policy of using skilled glassworkers from Europe, who would train the local employees—resulting in a superior workforce.

Former employees of the glassworks became the talent that established many of the region's glass factories, and many were company presidents or plant managers.

[100] To accomplish the change in window glassmaking, Owens hired Irving Wightman Colburn after purchasing his patents involved with the new process.

[110] Among former Hobbs employees involved with these companies were: Charles N. Brady, William S. Brady, Peter Cassell, Henry Crimmel, Benjamin M. Hildreth, Otto Jaeger, Nicholas Kopp Jr., William Leighton Jr., Lucian B. Martin, Harry Northwood, John Oesterling, Charles Henry Over, John Robinson, James B. Russell, and others.

[111] The charter for Hobbs, Brockunier and Company expired at the end of 1887—about the same time as the young workers at the plant went on strike, causing a shutdown.

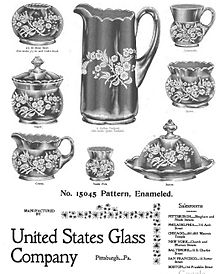

[117] The new firm was named United States Glass Company, and John H. Hobbs was on the board of directors.

[121] Two ways to make the plants produce products at lower prices were to get concessions from the unions and to introduce more machines.

The company showcased his work at the West Virginia State Fair in 1882, which included etched pitchers and wine glasses.