Jersey barrier

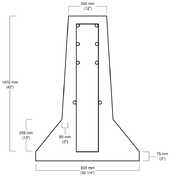

Taller variants, such as the Ontario Tall Wall, proved more effective at stopping vehicles and had the added advantage of blocking most oncoming headlights.

[6] Many are constructed with the embedded steel reinforcement protruding from each end, allowing them to be incorporated into permanent emplacements when linked to one another by sections of fresh concrete poured on-site.

Some dividers on county or local roads may have been lower than that, since they replaced a raised concrete rumble strip that would dissuade, but not prevent, traffic crossing from one lane to another.

[citation needed] The design of the Jersey barrier was specifically intended to minimize damage in incidental accidents and reduce the likelihood of a car crossing into oncoming lanes in the event of a collision.

In common shallow-angle hits, sheet-metal damage is minimized by allowing the vehicle tires to ride up on the lower sloped face.

[8] The states of New York, Massachusetts and New Jersey have adopted the taller barrier for their roads, as compared to the standard 32 inches (81 cm) suggested by the Federal Highway Administration.

[citation needed] During the US occupation of Iraq jersey barriers were set up in cities as form of urban warfare to combat Iraqi resistance.

[12] The department has marked all compliant precast concrete barrier walls with "350", indicating that they adhere to the requirements laid out in the National Cooperative Highway Research Program's Report 350.

These plastic barriers are normally filled with water after placement on-site to provide a moderate level of crash protection, then emptied prior to removal.