Job safety analysis

Examples of work assignments include "operating a grinder," "using a pressurized water extinguisher" or "changing a flat tire."

Consequence is the outcome of an event expressed qualitatively or quantitatively, being a loss, injury, disadvantage or gain.

For example, different levels of risk authorities may be assigned as follows: As low as reasonably practicable[4] when applied to job safety analysis means that it is not necessary to reduce risk beyond the point where the cost of further control becomes disproportionate to any achievable safety benefit.

[5] In relation to a duty to ensure health and safety, reasonably practicable means that which is, or was at a particular time, reasonably able to be done to ensure health and safety, taking into account and weighing up all relevant matters including:[6] PEPE is used to assist in identifying hazards.

Key factors for effective process are that the relevant components are in place, easy to follow and regularly reviewed and updated.

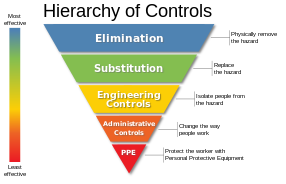

The effectiveness of a control is measured by its ability to reduce the likelihood of a hazard causing injury or damage.

A job safety analysis is a documented risk assessment developed when company policy directs employees to do so.

Analyses are usually developed when directed to do so by a supervisor, when indicated by the use of a first tier risk assessment and when a hazard associated with a task has a likelihood rating of 'possible' or greater.

These may include, but are not limited to, those with a history of, or potential for, injury, harm or damage such as those involving: It is important that employees understand that it is not the JSA form that will keep them safe on the job, but rather the process it represents.

The more minds and experience applied to analysing the hazards in a job, the more successful the work group is likely to be in controlling them.

A hazard is any factor that can cause damage to personnel, property or the environment (some companies include loss of production or downtime in the definition as well).

In the example below, the hazards are analyzed for the task of erecting scaffolding and welding lifting lugs: Some organizations add columns for risk levels.

Defining who is responsible for actually putting the controls in place that have been identified on the JSA worksheet ensures that an individual is accountable for doing so.

After the JSA worksheet is completed, the work group that is about to perform the task would have a toolbox talk, to discuss the hazards and controls, delegate responsibilities, ensure that all equipment and personal protective equipment described in the JSA are available, that contingencies such as fire fighting are understood, communication channels and hand signals are agreed etc.