Jointer

A jointer or in some configurations, a jointer-planer (also known in the UK and Australia as a planer or surface planer, and sometimes also as a buzzer or flat top) is a woodworking machine used to produce a flat surface along a board's length.

As a jointer, the machine operates on the narrow edge of boards, preparing them for use as butt joint or gluing into panels.

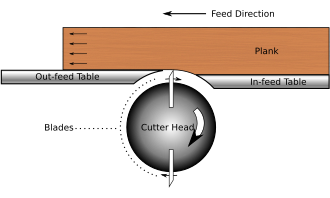

Fundamentally, a jointer's table arrangement is designed with two levels like a narrower thickness planer so that it consists of two long, narrow parallel tables in a row with a cutter head recessed between them, but with a side guide.

The cutting blades are adjusted to match the height and pitch of (& made square to) the outfeed table.

The cutter head's axis of rotation is parallel to the table surfaces and perpendicular to the feed direction.

The infeed and outfeed tables can be raised or lowered independently of each other and in relation to the cutter head although the outfeed table is normally set so that it is level with the knives when at the top dead centre of the rotation of the cutter head.

This procedure is often performed prior to edge jointing so that the board has a flat reference face for subsequent operations.

Jointers are also used for making rebates (also known as rabbets in North America) in finished timber.

A jointer that is used for rebating has the outside ends of its blades also sharpened and set with a small clearance from the cutter head.