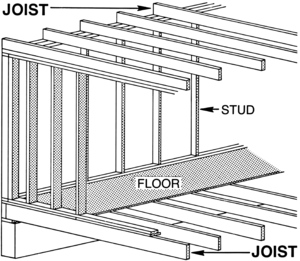

Joist

When incorporated into a floor framing system, joists serve to provide stiffness to the subfloor sheathing, allowing it to function as a horizontal diaphragm.

Typically, wood joists have the cross section of a plank with the longer faces positioned vertically.

The invention of the circular saw for use in modern sawmills has made it possible to fabricate wood joists as dimensional lumber.

Joists must exhibit the strength to support the anticipated load over a long period of time.

In many countries, the fabrication and installation of all framing members including joists must meet building code standards.

Lateral support called dwang,[1] blocking,[2] or strutting[2] increases its stability, preventing the joist from buckling under load.

The term binding joist is sometimes used to describe beams at floor level running perpendicular to the ridge of a gable roof and joined to the intermediate posts.

Joists left exposed and visible from below are called "naked flooring" or "articulated" (a modern U.S. term) and were typically planed smooth (wrought) and sometimes chamfered or beaded.