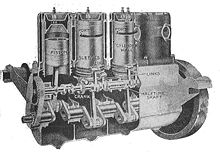

Knight engine

[1] At first Knight tried making the entire engine cylinder reciprocate to open and close the exhaust and inlet ports.

The sleeves are operated by small connecting rods actuated by an eccentric shaft and have ports cut out at their upper ends.

Continental declared the Single Sleeve-valve engines were cheaper and easier to manufacture than poppet valve motors, even though it used more oil at high speeds and was harder to start in cold weather.

[2] The engine's design allows a more central location for the spark plugs to provide a better flame path, large ports for improved gas flow and hemispherical combustion chambers that in turn allows increased power.

Much of the advantage to be gained from increased volumetric efficiency could not be realized due to the inability to transfer resultant heat in a sufficiently steep gradient to avoid excessive internal temperatures, however, Harry Ricardo pointed, about the single Sleeve-valve, Burt-McCollum type, that as long as oil film between Sleeve and cylinder wall is kept thin enough, sleeves are transparent to heat.

Improvements in design and materials of the more usual poppet valve engine eliminated most of the advantages initially held by the sleeve-valved variant, so that by the early 1930s manufacture of the Silent Knight had ceased, with only a couple of French automobile makers continuing to the end of the 1930's.

Pierce-Arrow of Buffalo, New York tested the engine against one of their own and found that it was more powerful at speeds above 30 miles per hour (50 km/h) and would also go faster.

Knight also received some bad publicity at the same time when a prototype car was entered in the 1906 Glidden Tour, only to drop out on the first day due to mechanical failure.

To combat criticism from its competitors, Daimler had the RAC (Royal Automobile Club) carry out their own independent tests on the Daimler-Knight.

The same engines were then installed in a touring car and driven for 2,000 miles (3,200 km) on the Brooklands race track, after which they were removed and again run on the bench for 5 hours.

[6] The RAC reports caused Daimler's share price to rise, £0.85 to £18.75,[1] and the company's competitors to fear that the poppet-valve engine would soon be obsolete.

Daimler contracted Dr. Frederick Lanchester as their consultant for the purpose and a major re-design and refinement of Knight's design took place in great secrecy.

In 1913 a Mercedes-Knight driven by Théodore Pilette was entered in the Indianapolis 500 where, despite having the smallest engine, it took fifth place averaging 68.148 mph (109.674 km/h) over the 500 miles (800 km).

The Knight engine, while it originated in USA, was developed to fruition in England[9] gaining an earlier start in Europe, where it also lasted longer.

In France, besides Peugeot and Mors, two brands of luxury automobiles used the Knight engine as standard equipment between 1923 and 1940: Avions Voisin and Panhard et Levassor.

(1909 example) the mascot on its radiator cap is (C. Y.'s) Knight