Knitting machine

There are numerous types of knitting machines, ranging from simple spool or board templates with no moving parts to highly complex mechanisms controlled by electronics.

All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity.

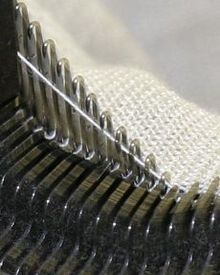

Early flat bed stocking frames had low carbon steel bearded needles where the tips were reflexed and could be depressed onto a hollow closing the loop.

Ribbing attachments can be added to single bed machines to achieve a similar result.

By means of various selection methods, e.g. punch cards, particular needles can be caused to travel by alternate pathways through the cam box.

Knitweaving refers to a technique in which a separate piece of yarn, often heavier than the knitted fabric, is carried along and caught between stitches to produce an effect like weaving.

Current standard gauge models have the option of a lace carriage, where stitches can be transferred from one needle to the next.

This type of machine adds extra metallic elements which are called holding hooks.

In the 2010's, a new technology for industrial flatbed machines emerged which enabled fully finished garments to be knit in one piece with no assembling.

In 2016, Fast Retailing, the parent company of Uniqlo, signed a deal with Shima Seiki to develop a factory of WHOLEGARMENT 3D knitting machines for mass-producing garments.

On a single-bed domestic knitting machines, garter stitch must be either worked by hand or using an accessory called a 'garter bar'.

Certain models of Garter carriages can be used on both mechanical and electronic Brother knitting machines.