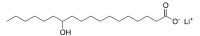

Lithium 12-hydroxystearate

Lithium soap greases are preferred for their water resistance, and their oxidative and mechanical stability.

With vigorous stirring, dilute monohydrate lithium hydroxide is gradually added to a dispersion of the fatty acid in water heated to slightly below boiling.

[2] Since these lithium soaps are difficult to filter, they are collected by spray drying.

The synthetic oils are preferred for their greater stability and ability to perform at extreme temperatures.

[3] This process converts ricinoleate moieties in castor oil triglycerides to 12-hydroxystearate, with stearate as a byproduct from dehydration of the hydroxy acid followed by hydrogenation.