Lithium Tokamak Experiment

One of the ongoing research issues for commercial fusion power development is the choice of material for the plasma-facing portions of the reactor vessel, also known as the first wall.

Most reactors operate at the equivalent of a high vacuum and thus demand high-strength materials to resists the inward pressure of the magnets against the empty interior.

Finally, flowing liquid lithium can also potentially handle the high power densities expected on reactor walls.

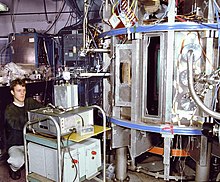

[1] To achieve more a complete non-recycling PFC, the CDX-U vacuum vessel was disassembled for the installation of a heated inner shell inside it.

The stainless steel plasma-facing surface of the inner LTX shell will be coated with lithium between shots, using an electron beam evaporator.

[2] The upgrade increased the magnetic field by about two thirds, and added 500 kW of neutral beam injector heating.